The cover image was created by the transcriber and is placed in the public domain.

The Project Gutenberg EBook of Stone Art, by Gerard Fowke

This eBook is for the use of anyone anywhere in the United States and most

other parts of the world at no cost and with almost no restrictions

whatsoever. You may copy it, give it away or re-use it under the terms of

the Project Gutenberg License included with this eBook or online at

www.gutenberg.org. If you are not located in the United States, you'll have

to check the laws of the country where you are located before using this ebook.

Title: Stone Art

Thirteenth Annual Report of the Bureau of American Ethnology

to the Secretary of the Smithsonian Institution, 1891-1892,

Government Printing Office, Washington, 1896, pages 47-178.

Author: Gerard Fowke

Release Date: December 26, 2015 [EBook #50769]

Language: English

Character set encoding: UTF-8

*** START OF THIS PROJECT GUTENBERG EBOOK STONE ART ***

Produced by PM for Bureau of American Ethnology, The

Internet Archive (American Libraries) and the Online

Distributed Proofreading Team at http://www.pgdp.net (This

file was produced from images generously made available

by the Bibliothèque nationale de France (BnF/Gallica) at

http://gallica.bnf.fr)

47

The cover image was created by the transcriber and is placed in the public domain.

48

49

51

56

57

STONE ART

By Gerard Fowke

The collection of the Bureau of Ethnology includes almost every type of stone implement or ornament, and as the investigations and explorations of the collaborators have extended over nearly all the eastern and central portions of the Mississippi valley, it furnishes a substantial basis for showing the geographic distribution of various forms of objects in use among the aboriginal inhabitants.

It has not been deemed advisable to utilize material contained in other collections. Should this be done there would be no reason for drawing upon one rather than another, and if it were once begun the examination would finally extend to every collection made from American localities, a study which, although perhaps desirable, would transcend the scope of the Bureau plans.

Much that has been published in regard to the distribution of relics in various portions of the country is of little value to a paper of this kind, since few of the objects are sufficiently illustrated or referred to any class in other than the most general terms; so that it is frequently impossible to determine the group in which a given article should be placed. Partly for this reason, partly because the primary purpose is description of a certain collection made in a definite way, little space is given to the descriptive work of predecessors in the field of archeology. The general results of previous work are, however, carefully weighed in the conclusions reached.

The ordinary division into chipped and pecked or ground implements has been adopted: the former including all such as are more easily worked by flaking, and the latter including those made from stone suitable for working down by pecking into form with stone hammers or by similar means. The system of nomenclature in general use has been retained, as it is now familiar to students of North American 58 archeology, and, while not entirely satisfactory in some respects, is perhaps as good as can be devised in the present state of knowledge.

Careful study of the entire collection has failed to show the slightest difference in the form, finish, or material of implements from the same locality, whether found in mounds or graves or on the surface; hence no attempt is made to separate the two classes of objects. Allowance is to be made for the weathering of a surface specimen, but this is the only distinction.

It is not always easy to identify a stone, even with a fresh surface; in a weathered specimen it is often impossible. For this reason the material of which a specimen is made may not be correctly named; frequently the alteration due to exposure will change the appearance of a rock very much, and in such a case the best that can be done is to tell what it looks most like. The material of a majority of specimens however, or at least the classes of rock to which they belong, as granite, porphyry, etc., are correctly named; to give a more exact name would be possible only by the destruction or injury of the specimen. There are a few terms used which may be here explained.

“Compact quartzite” is a very hard, close-grained, siliceous rock, sometimes nearly a flint, and again closely approaching novaculite. “Greenstone” may be diorite or diabase, or it may be a very compact dark sandstone or quartzite so weathered that its nature can not be determined from superficial observation. “Argillite” refers to any slaty rock; it may be so soft as to be easily cut with a knife, or nearly as hard as quartzite. Usually it is greenish in color.

A comprehensive study of all available collections will no doubt modify materially the classification and system of types here presented.

The quotations from eminent anthropologists given below show the difficulties in the way of establishing a satisfactory system of types, or of assigning certain forms to particular localities. In most of these quotations the substance only of the author’s remarks is given.

According to Dr. E. B. Tylor, the flint arrows of the Dakota, the Apache, or the Comanche might easily be mistaken for the weapons dug up on the banks of the Thames;1 while cores of flint in Scandinavia and of obsidian in Mexico are exactly alike,2 and a tray filled with European arrowheads can not be distinguished from a tray of American ones.3 Prof. Otis T. Mason observes that the great variety of form in such weapons after they are finished is due partly to nature and partly to the workman’s desire to produce a certain kind of implement. All sorts of pebbles lie at the hand of the savage mechanic, none of them just what he wants. He selects the best.4 Perhaps the truth about the shape is that the savage found it thus and let it so remain.5 59

The state of things among the lower tribes which presents itself to the student is a substantial similarity in knowledge, arts, and customs, running through the whole world. Not that the whole culture of all tribes is alike—far from it; but if any art or custom belonging to a low tribe is selected at random, the likelihood is that something substantially like it may be found in at least one place thousands of miles off, though it frequently happens that there are large intervening areas where it has not been observed.6

On the whole, it seems most probable that many of the simpler weapons, implements, etc., have been invented independently by various savage tribes. Though they are remarkably similar, they are at the same time curiously different. The necessaries of life are simple and similar all over the world. The materials with which men have to deal are also very much alike; wood, bone, and to a certain extent stone, have everywhere the same properties. The obsidian flakes of the Aztecs resemble the flint flakes of our ancestors, not so much because the ancient Briton resembled the Aztec, as because the fracture of flint is like that of obsidian. So also the pointed bones used as awls are necessarily similar all over the world. Similarity exists, in fact, rather in the raw material than in the manufactured article, and some even of the simplest implements of stone are very different among different races.7

Tylor again says:

When, however, their full value has been given to the differences in the productions of the Ground Stone Age, there remains a residue of a most remarkable kind. In the first place, a very small number of classes, flakes, knives, scrapers, spear and arrow heads, celts, and hammers take in the great mass of specimens in museums; and in the second place, the prevailing character of these implements, whether modern or thousands of years old, whether found on this side of the world or on the other, is a marked uniformity. The ethnographer who has studied the stone implements of Europe, Asia, North or South America, or Polynesia, may consider the specimens from the district he has studied as types from which those of other districts differ, as a class, by the presence or absence of a few peculiar instruments, and individually in more or less important details of shape or finish, unless, as sometimes happens, they do not differ perceptibly at all. So great is this uniformity in the stone implements of different places and times, that it goes far to neutralize their value as distinctive of different races. It is clear that no great help in tracing the minute history of the growth and migration of tribes is to be got from an arrowhead which might have come from Polynesia, or Siberia, or the Isle of Man, or from a celt which might be, for all its appearance shows, Mexican, Irish, or Tahitian. If an observer, tolerably acquainted with stone implements, had an unticketed collection placed before him, the largeness of the number of specimens which he would not confidently assign, by mere inspection, to their proper countries, would serve as a fair measure of their general uniformity. Even when aided by mineralogical knowledge, often a great help, he would have to leave a large fraction of the whole in an unclassified heap, confessing that he did not know within thousands of miles or thousands of years where and when they were made.

How, then, is this remarkable uniformity to be explained? The principle that man does the same thing under the same circumstances will account for much, but 60 it is very doubtful whether it can be stretched far enough to account for even the greater proportion of the facts in question. The other side of the argument is, of course, that resemblance is due to connection, and the truth is made up of the two, though in what proportion we do not know.8

While the several authors quoted do not fully agree, and some are even slightly self-contradictory, still, if the statements are to be taken at their face value, it would seem that efforts to make such classifications are mainly a waste of time.

It may be premised that in every class of implements there are almost as many forms as specimens, if every variation in size or pattern is to be considered; and these merge into one another imperceptibly. Not only is this the case with individual types, but the classes themselves, totally unlike as their more pronounced forms may be, gradually approach one another until there is found a medium type whose place can not be definitely fixed.

As space would be needlessly occupied by attempting to name each county, the area from which specimens have been obtained is, for convenience, divided into districts. These divisions are for use in this article only, and are not intended as archeologic districts.

In the tables given under each heading, the names of counties or districts show where the types described are obtained; the columns following show the number of specimens of each material mentioned in the collection of the Bureau.

Where a limited area only has been examined in any division, the name of the county is usually given; but where specimens of any kind have been obtained from different counties near one another, they are assigned to the district including those counties. The districts are as follows:

Northeastern: Between White and Mississippi rivers.

Southeastern: Between White and Washita rivers from Clarendon to Arkadelphia.

Southwestern: West of Washita river and south of Arkadelphia, including Bowie and Red River counties, Texas.

Central: From Dardanelles southward and eastward to the above limits.

Northeastern: Bordering Tennessee river east of Decatur.

Northwestern: Bordering Tennessee river west of Decatur. 61 Coosa: Bordering Coosa river southward to and including Dallas county.

Tuscaloosa: Bordering the Tuscaloosa and Little Tombigbee, and extending a short distance below their confluence.

Miami valley: The country along the two Miami rivers, including Shelby county on the north and Madison and Brown counties on the east.

Scioto valley: South of Franklin county, including Adams and Lawrence counties.

Central: Including Union, Knox, Perry, and Franklin counties, and the area within these limits.

Southwestern: The counties bordering on either side of Mississippi river from La Crosse to Dubuque (Iowa).

Eastern: The portion between Lake Michigan, Lake Winnebago, and the Illinois line.

Southern: Dane and adjoining counties.

Keokuk: The southeastern corner of the state and adjacent portions of Illinois and Missouri.

Eastern: All the mountain district, with the extreme southwestern part of Virginia.

Western: From Mississippi river to and including the tier of counties east of the Tennessee.

Northern: The northern half of the interior portion.

Southern: The southern half of this portion.

Northwestern: North and west of a line from Lancaster to Columbia. As no other portion of the state has been examined under direction of the Bureau, only the name of the state is used herein, reference being always to this section.

Northwestern: The portion northwest of the Chattahoochee.

Southwestern: Area contiguous to the lower Chattahoochee and Flint river.

Savannah: The vicinity of the city of Savannah, where a large collection was gathered.

62

Northeastern: Between Kentucky, Big Sandy, and Ohio rivers.

Southeastern: From Estill and Cumberland counties to the Tennessee and Virginia state lines.

Central: Between Green and Ohio rivers, west of the last described districts.

Southern: From Green river southward and as far westward as Christian county.

Western: West of Green river and Christian county.

Western: West of Charlotte.

Central: Between Charlotte and Raleigh.

Southwestern: From the mouth of the Cumberland to Washington county, and thence to the Mississippi.

The various forms of implements will now be considered. As stated above, the names given the various articles are those by which they are usually known; but it may be well to define some of the terms used.

In the grooved axes, edge refers to the cutting portion; blade, to the part below the groove; poll or head, to that above the groove; face, to the wider or flat portion of the surface; side, to the narrower part; front, to that side farther from the hand, and back, to the side nearer the hand when in use.

In celts, the terms are the same, so far as they are applicable; blade referring to the lower half of the implement; that is, to the portion on which the cutting edge is formed.

The implements known as grooved axes seem to be of general distribution throughout the United States; being, so far can be learned from various writers, much more numerous east of Mississippi river than west of it. It must be remembered, however, that thousands of diligent collectors have carefully searched for such things in the east, while in the west little attention has been paid to them; consequently, deductions are not to be made concerning their relative abundance or scarcity, until further knowledge is gained. The same remark will apply to every form of aboriginal relic. 63

In the eastern and interior states, the grooved axes are far more abundant than the celts of the same size9, because as a rule only the larger implements of this class are grooved. All the ordinary varieties of axes and hatchets are found about Lake Champlain, by far the most abundant being celts, or grooveless axes.10

According to Adair and other early observers, the southern Indians had axes of stone, around the grooved heads of which they twisted hickory withes to serve as handles; with these they deadened timber by girdling or cutting through the bark.11 According to travelers of a later generation among the western Indians, similar implements were used on the plains to chop up the vertebræ of buffaloes, which were boiled to obtain the marrow.12

These statements, which might be multiplied, show that such objects are to be found widely scattered; none, however, give information more definite than that the axes are “grooved,” no reference being made to the shape of the ax or the manner of grooving.

The various modes of mounting axes and celts in handles are illustrated in the Smithsonian Report for 1879.

Stone axes were used in Europe by the Germans at as late a period as the Thirty Years’ war, and are supposed to have been used by the Anglo-Saxons at the battle of Hastings.13

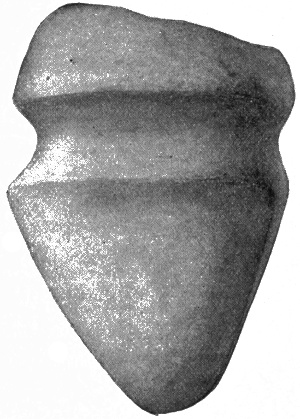

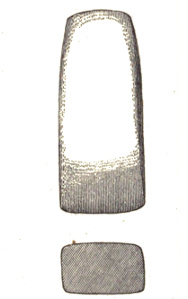

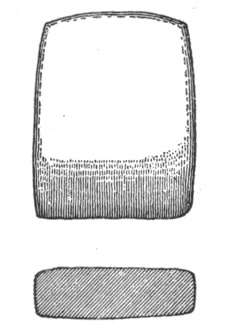

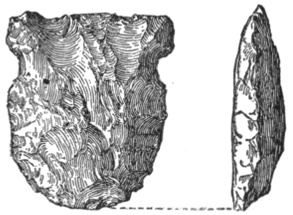

Fig. 29.—Grooved ax, showing groove projections.

Axes having two grooves occur in considerable numbers in the pueblos of southwestern United States, but they are extremely rare elsewhere and unknown in most districts; as the objects are generally small, the utility of the second groove is not evident.

The arrangement of stone axes may be based upon the manner of forming the groove. In one class are placed those which in the process of making had a ridge left encircling the weapon, in which the groove was formed. This gives the ax greater strength with the same material. Usually the groove has been worked just deep enough to reach the body of the ax; that is, to such a depth that should the projections be ground off there would remain a celt-like implement (as shown in 64 figure 29, of chlorite-schist, from Sullivan county, Tennessee). The axes of this class in the Bureau collection are shown in the following table:

| District. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Eastern Tennessee | 9 | 8 | 4 | 5 | 1 | |

| Western North Carolina | 1 | 1 | ||||

| Central North Carolina | 1 | 1 | ||||

| Savannah, Georgia | 4 | 1 | ||||

| Butler county, Ohio | 1 | 1 | ||||

|

KEY: A = Greenstone. B = Argillite. C = Sienite. D = Granite. E = Schist. F = Quartzite. |

||||||

In the second class the groove is formed by pecking into the body of the ax after the latter is dressed into shape; in this pattern a regular continuous line from edge to poll would touch only the margins of the groove, leaving it beneath. An apparent medium between the two is sometimes seen, in which there is a projection on the lower side of the groove only; this is due, usually, to dressing the blade down thinner after the implement was originally worked to a symmetric outline. By continuous or long use the edge of the ax becomes broken or blunted and requires sharpening, and in order to keep the proper outline to make the tool efficient, it is necessary to work the blade thinner as it becomes shorter. No such change is required in the poll, consequently a projection is formed where originally there was no trace of one.

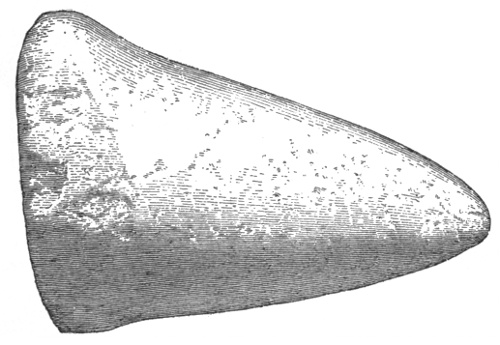

Fig. 30.—Grooved ax, showing pointed edge.

There are different methods of finishing the ax, which may appear with either form of groove. The poll may be worked into the shape of a flattened hemisphere, may be flat on top, with the part between the groove and the top straight, convex or concave, or may be worked to a blunt point, with straight or concave lines to the groove. The blade may taper from the groove to the edge, with straight or curved sides, which may run almost parallel or may be drawn to a blunt-pointed edge. This latter form is probably due to breaking or wearing of the blade, which is reworked, as shown in figure 30, of granite, from Boone county, Missouri.

There are a very few specimens, as noted below, in which the ax gradually increases in width from the poll to the edge; but such specimens seem to be made of stones which had this form approximately at the beginning, and were worked into such shape as would give a suitable implement with the least labor.

In nearly every instance the groove of an ax with a groove projection extends entirely around with practically the same depth, and the blade 65 of the ax has an elliptical section. There are, however, a few with the back flattened; and while many of the second division may be similar in section, and in having the groove extend entirely around, yet in this class are to be placed nearly all of those only partly encircled by a groove or showing some other section than the ellipse.

Fig. 31.—Grooved ax, showing groove entirely around.

Fig. 32.—Grooved ax, slender, showing groove entirely around.

With these exceptions, the second class of grooved stone axes comprises seven groups, which may be described and tabulated as follows:

A. Grooved entirely around, elliptical section, polls dressed in any of the ways given above; three or four have the blunt-pointed edge (figure 31, of granite, from Bradley county, Tennessee).

| District. | A | B | C | D | E | F | G | H | I |

|---|---|---|---|---|---|---|---|---|---|

| Southwestern Illinois | 1 | 1 | 1 | ||||||

| Eastern Tennessee | 4 | 3 | 2 | 2 | 15 | 4 | 1 | ||

| Central North Carolina | 1 | 1 | |||||||

| Western North Carolina | 2 | 2 | |||||||

| Central Arkansas | 1 | 1 | |||||||

| Ross county, Ohio | 1 | ||||||||

| Green River, Kentucky | 1 | 1 | |||||||

| Northeastern Kentucky | 1 | 1 | |||||||

| Kanawha valley, West Virginia | 4 | 1 | 1 | 1 | |||||

| Keokuk district, Iowa | 1 | 1 | |||||||

| Savannah, Georgia | 1 | 2 | 6 | 3 | |||||

| Miami valley, Ohio | 2 | 5 | 1 | ||||||

|

KEY: A = Greenstone. B = Granite. C = Diorite. D = Sandstone. E = Quartzite. F = Argillite. G = Slate. H = Sienite. I = Porphyry. |

|||||||||

66

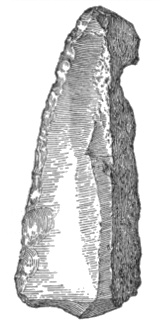

B. Long, narrow, and thin, giving a much flattened elliptical section. These are classed with axes on account of the grooves, although too thin and usually of material too soft to endure violent usage. The edges are nicked, striated, or polished, as though from use as hoes or adzes (figure 32, of argillite, from Bradley county, Tennessee).

| District. | A | B | C |

|---|---|---|---|

| Eastern Tennessee | 18 | 1 | |

| Keokuk district, Iowa | 1 | ||

| Kanawha valley, West Virginia | 1 | ||

| Montgomery county, North Carolina | 1 | ||

| Western North Carolina | 1 | ||

| Butler county, Ohio | 2 | ||

|

KEY: A = Granite. B = Argillite. C = Slate. |

|||

Fig. 33.—Grooved ax, showing grooved back.

Fig. 34.—Grooved ax, showing grooved back.

C. Grooved on both faces and one side; back hollowed, usually in a straight line the whole length; front drawn in from the groove to give a narrower edge (figures 33, of porphyry, from Brown county, Ohio, and 34, of granite, from Kanawha valley, West Virginia).

| District. | A | B | C | D |

|---|---|---|---|---|

| Eastern Tennessee | 1 | 1 | ||

| Kanawha valley, West Virginia | 1 | 1 | ||

| Butler county, Ohio | 1 | |||

| Brown county, Ohio | 1 | |||

|

KEY: A = Granite. B = Argillite. C = Sienite. D = Porphyry. |

||||

67

D. Same method of grooving; back is rounded, and may be in a straight or curved line the entire length, or a broken line straight in each direction from the groove. The type is illustrated by figure 35, of granite, from Keokuk, Iowa. This specimen is unusually wide and thin; generally the outlines are similar to those last described.

| District. | A | B | C |

|---|---|---|---|

| Eastern Tennessee | 5 | ||

| Butler county, Ohio | 2 | ||

| Keokuk district, Iowa | 1 | 1 | |

|

KEY: A = Granite. B = Argillite. C = Sienite. |

|||

Fig. 35.—Grooved ax, showing rounded back.

E. Grooved like the last; same general form, except that the back is flat (figures 36, of sienite, from Brown county, Ohio, and 37, of granite, from Drew county, Arkansas).

| District. | A | B | C | D | E |

|---|---|---|---|---|---|

| Miami valley, Ohio | 2 | 3 | 5 | ||

| Brown county, Ohio | 1 | ||||

| Keokuk district, Ohio | 1 | 1 | |||

| Brown county, Illinois | 1 | 2 | |||

| Eastern Tennessee | 2 | 2 | |||

| Kanawha valley, West Virginia | 4 | 1 | 2 | ||

| Savannah, Georgia | 1 | 1 | |||

| Northeastern Kentucky | 1 | ||||

| Licking county, Ohio | 1 | ||||

|

KEY: A = Sandstone. B = Argillite. C = Granite. D = Sienite. E = Greenstone. |

|||||

68

F. Grooved on both faces and one side, with both sides flat. There is only one of this form in the collection; it is of argillite, from Keokuk, Iowa.

G. Grooved on faces only, with both sides flat (figure 38, of granite, from Keokuk, Iowa). There are from the same place one of porphyry, one of argillite, and three of sienite. This and the preceding form seem peculiar to that locality.

Fig. 36.—Grooved ax, showing flattened curved back.

Fig. 37.—Grooved ax, showing flattened straight back.

There are a few exceptional forms which are not placed with those just given, since they may have some features common to all except the Keokuk type, while in other respects they differ from all. Among them are some entire-grooved or grooved only on the two sides and one face; the general outline may correspond with some of the regular forms, but one face is curved from poll to edge, while the other is straight or nearly so (figure 39, of granite, from Wilkes county, North Carolina). This specimen has a depression, as if worn by the end of a handle, on the straight face at the lower edge of the groove.

None of this form are long enough for hoes, and although they may have been used for axes and hatchets, their shape seems to indicate use as adzes. Besides the one figured there are two from Savannah, Georgia; three from eastern Tennessee, one with a slight groove and very deep side notches; and three from western North Carolina, two of them entire-grooved with groove projections. 69

Fig. 38.—Grooved ax, Keokuk type.

Fig. 39.—Grooved ax, showing adze form.

Another unusual form, which may come under any of the foregoing figures, has the groove crossing the implement diagonally, in such a way as to cause the blade to incline backward (figure 40, of granite, from Carter county, Tennessee). Besides the specimen illustrated, this form is also represented by one of granite from northwestern North Carolina with projection for groove; two of argillite from southwestern Tennessee; one, widest at edge, from Savannah, Georgia; one from Ross county, Ohio; and two of granite, highly polished, grooved on faces and one side, with backs flat, from Kanawha valley, West Virginia.

Of the axes wider at the edge than at any point above (of which the specimen illustrated in figure 41, of granite, from a grave at Kingsport, Tennessee, may be taken as a type,) there are one of diorite from Kanawha valley, West Virginia, which seems to have been of ordinary pattern but broken and redressed to its present form; and from Savannah, Georgia, one of uniform taper with diagonal groove, and one widening irregularly until the blade is fully twice the width of the poll.

Fig. 40.—Grooved ax, showing diagonal groove.

Fig. 41.—Grooved ax, showing wide edge.

Many, if not a majority, of the entire-grooved axes have the groove wide enough for a very large handle, or for an ordinary withe to be twisted twice around. In those which have one side ungrooved, the intention was to admit a wedge between the stone and the curve of the handle. The handles were very firmly fastened; two axes in the collection have been broken in such a way that on one side, from the top half way down, the blade is gone, carrying away the groove on that side; yet the polish of the groove extends 70 over the fractured surface, which has never been reworked, showing that the tool was long used after this accident. As the handles could easily slip off over the top in specimens thus broken, they must have been tightly lashed; perhaps gum or glue was used.

Fig. 42.—Grooved ax, showing curved edge.

Partly finished specimens show that the groove was pecked out and the edge ground before the remaining parts of the ax were worked. Some have the edge ground sharp and the groove worn smooth or even polished by long use, while all the rest of the implement retains the original weathered surface. A stone was always chosen that could be brought to the desired form with the least labor, and very often one could be found that required but little work to make a very satisfactory weapon or implement or even ornament.

Occasionally specimens indicate by the manner of wear their application to certain kinds of work. Sometimes the edge is curved by the wearing away of one face until it has almost a gouge form; sometimes the side of the blade next the hand, again that farthest away, is more worn. This in time would give the blunt-pointed edge. A peculiar finish of the lower part of the blade, which is also seen in a few celts, is shown in figure 42, of sienite, from Carter county, Tennessee. One half of each face has been left full, and the part opposite hollowed out, giving an ogee curve to the edge. Figure 43, of granite, from Jefferson county, Tennessee, seems to have a ridge on the upper side of the groove; but closer examination shows that it once had a groove projection, and that afterwards the poll was nearly all broken away and a new groove made lower down, so that what was originally the lower projection is now above the groove, the remainder of the poll being worked down to a point.

There are a few hammers which differ from the ordinary ax only in being blunt instead of sharp. They may be nothing more than broken axes, utilized as hammers instead of being resharpened.

Fig. 43.—Grooved ax, showing single groove projection.

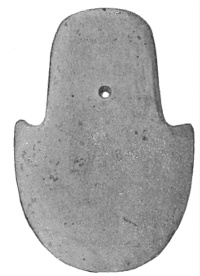

Under this head may be placed implements plainly used as adzes. They are much longer than axes in proportion to their other dimensions, have one face convex, the other straight or concave. They may be placed in the same class as the specimen shown in figure 39, and also those represented in figures 44 and 45, from McMinn county, Tennessee. There is also a similar adze from Saline county, Arkansas. All the specimens of this class are of argillite. 71

With the grooved axes is also placed a class of implements that may be called axes notched on the sides. Many of them were no doubt used as sinkers; but some of the same form, size, and material have the notches and sometimes portions of the face worn perfectly smooth, while frequently they are ground to a sharp edge. Again, even in those that have not the least polish, the edge shows marks that would seem to result from use as axes, adzes, or hoes.

There are three divisions of this class of implements, as follows:

A. Unworked, except notches; probably sinkers.

| District. | A | B | C | D |

|---|---|---|---|---|

| Eastern Tennessee | 1 | 5 | ||

| Montgomery county, North Carolina | 1 | |||

| Northeastern Alabama | 5 | |||

| Kanawha valley, West Virginia | 3 | |||

|

KEY: A = Sandstone. B = Argillite. C = Quartzite. D = Limestone. |

||||

B. Partly ground sharp edges, mostly with polished notches, sometimes with faces polished from one notch to the other (figure 46, of argillite, from Cocke county, Tennessee). In addition there are 11 examples of argillite, besides one of mica-schist from eastern Tennessee and another of sandstone from Savannah, Georgia.

Fig. 44.—Grooved adze.

Fig. 45.—Grooved adze, showing curved blade.

C. Roughly chipped, with notches often at the middle but sometimes nearer one end. Probably most of these were sinkers; but as above stated the edges show marks of use, apparently in scraping, digging, or striking. Of these the following examples are in the Bureau collection: From several localities in eastern Tennessee, 40 of argillite; from Montgomery county, North Carolina, 24 of argillite and quartzite; 72 from Kanawha valley, West Virginia, and from Savannah, Georgia, a few specimens of the same materials.

What is true of the uses and distribution of stone axes applies with much the same force to what are called celts—not a good descriptive term, but one which is now given to the implement in lieu of something better. It would appear difficult or impossible to do with these rude tools any work for which we commonly use an ax or hatchet; and yet, by the aid of fire, or even without it, the aborigines contrived to accomplish a great deal with them.

The Maori of New Zealand do all their wonderful work of wood carving with only a chisel or adze (of stone or shell).14 Among the Iroquois, in cutting trees, fire was applied at the root, the coals were scraped away with a chisel, and this process was repeated until the tree was felled. The trunk was divided into lengths in the same way. Similarly canoes and mortars were hollowed out.15 The Virginia Indians at an early day employed a similar process. They also cleared ground for cultivation by deadening trees with their tomahawks,16 and used adzes made of shell in cleaning out the charred wood in making canoes.17 The Nootka of the northwestern part of the continent in felling a tree use a flint or elkhorn set in a handle, this being struck with a stone mallet. In hollowing canoes a musselshell also is used as an adze, and sometimes fire is applied. The outside is shaped by similar means.18

Fig. 46.—Notched ax, showing polished edge.

Stone chisels have been found in various steatite quarries, where vessels and other utensils of this material were made, and the marks of their use is plain both on the vessels in an unfinished state and on the cores, as well as on the quarry face.19

The different ways of hafting, as shown by specimens in the Bureau collection, were as follows:

(1) A hole was cut entirely through a stick and the celt was inserted so that it would project on both sides;

(2) The hole was cut partly through, and the celt was pushed in as far as it would go; 73

(3) The top of the celt was set in a socket of deer horn, which was put into a handle as in form 2;

(4) Small celt-shaped knives or scrapers were set into the end of a piece of antler long enough to be used as a handle;

(5) A forked branch was so cut as to make two prongs of nearly equal length, and the celt was fastened to the end of one, parallel with it, the other being used to guide and steady it, a prong being held in each hand;

(6) The fork of a root or branch was trimmed so as to make a flat face at any desired angle, to which the celt was lashed, a shoulder, against which the end of the celt was set, being sometimes cut in the wood;

(7) A stick was split its entire length and a single turn taken around the celt, the ends being brought together and tied, forming a round handle;

(8) A stick was split part way, one fork cut off and the other wrapped once or twice and tied, thus forming a round handle of solid wood.

Fig. 47.—Celt, showing blade thick near edge.

Fig. 48.—Celt, showing blade thick near edge.

Forms 5 and 6 were used as adzes; forms 7 and 8 are the same methods as employed in hafting grooved axes.

A mounting similar to form 4 is seen in some Alaska specimens of celt-scrapers in which the implement is fastened to a piece of wood so as to project a short distance, and used like a plane. In all these, the celt is very firmly fastened to the handle with sinew or rawhide, which, when put on green, contracts with great force and binds like wire.

As to the forms of celts, no division is practicable based on anything but their entire appearance. The following descriptions and tabulations represent the material of this kind in the Bureau collection:

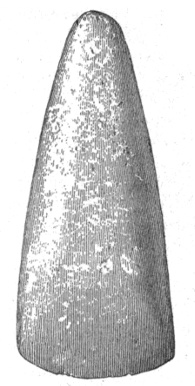

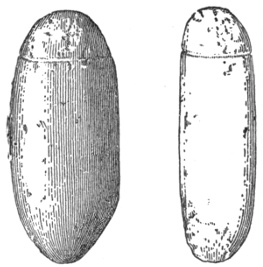

A. Round or nearly round section, pointed or flattened at the top, blade rapidly thickening from the edge; a few are polished at the top, but most of them show marks of a maul or hammer; all have been highly polished; all of this class were probably used as wedges, as their shape renders them more fit for this purpose than for any other; the 74 battered tops indicate such usage. The few not showing such marks may have been set into a bumper of wood or horn, or used with wooden mauls. They vary in length from 2½ to 7½ inches. They are represented by the specimen shown in figure 47, of argillite, from Lincoln county, Arkansas; there are also one from a mound in Sumter county, Alabama (figure 48), and one from Kanawha valley, West Virginia, both of serpentine and elliptical in section, though the form of the edge puts them in this class. The following specimens are typical representations of the class:

| District. | A | B | C | D | E |

|---|---|---|---|---|---|

| Northwestern North Carolina | 3 | 7 | 2 | ||

| Eastern Tennessee | 3 | ||||

| Western Tennessee | 1 | ||||

| Southeastern Arkansas | 2 | ||||

| Union county, Mississippi | 1 | ||||

| Madison county, Illinois | 1 | ||||

| Savannah, Georgia | 2 | 1 | |||

|

KEY: A = Sienite. B = Argillite. C = Granite. D = Rotten limestone. E = Sandstone. |

|||||

Fig. 49.—Celt, showing long, slender form.

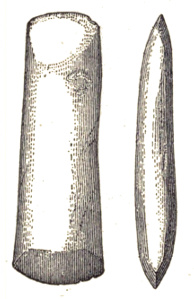

B. Long, narrow, elliptical section, pointed top, curved or straight edges, sides straight or gently curved. None of these seem to have been put to any rough use, as the edges are quite sharp and the entire surface is well polished; length from 4¼ to 12½ inches. The type is illustrated by figure 49, of argillite, from a mound in Monroe county, Tennessee.

| District. | A | B | C | D | E |

|---|---|---|---|---|---|

| Eastern Tennessee | 8 | 3 | |||

| Northwestern Georgia | 1 | ||||

| Savannah, Georgia | 6 | 1 | 3 | ||

| Kanawha valley, West Virginia | 1 | ||||

| Northeastern Alabama | 1 | ||||

| Western North Carolina | 1 | ||||

|

KEY: A = Argillite. B = Granite. C = Sandstone. D = Quartzite. E = Sienite. |

|||||

C. Thick, almost round section, round-pointed top, nearly straight to sharp-curved edge, sides gently curved, widest at edge or just above. Most of these show marks of use as cutting tools or hatchets. In 75 many the top has been roughened as if for insertion into a hole cut in a piece of wood; others have this roughening around the middle or immediately above, leaving a polish at both ends, and these were hafted probably by means of a stick or withe twisted around them. The roughening is a secondary operation, having no relation to the making of the implement; it was produced by pecking after the surface was polished. In a few cases it extends from the top well down the sides; but usually it reaches but a little way below the top, or else is in a circle around the body of the celt. Most of them have sharp edges; a few have edges either chipped or blunted and polished, showing long usage. Two from Kanawha valley (one roughened for handle) have the edges worn in on one of the faces until they almost resemble gouges; but that they were not intended as such is shown by the concavity being nearer one side and not reaching entirely across. The length ranges from 4½ to 10 inches. The type is illustrated by figures 50 and 51, both of sienite, from Lauderdale county, Tennessee.

Fig. 50.—Celt, nearly round section.

Fig. 51.—Celt, nearly round section.

This may be regarded as the typical form of celt for eastern United States, and its geographic distribution is exceptionally wide, as shown in the table.

The Bureau collection includes the following specimens of this class:

| District. | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| Western North Carolina | 4 | 2 | 9 | 16 | ||||

| Montgomery county, North Carolina | 1 | |||||||

| Coosa district, Alabama | 1 | |||||||

| Ross county, Ohio | 1 | |||||||

| Knox county, Ohio | 1 | |||||||

| Miami valley, Ohio | 1 | 2 | ||||||

| Eastern Tennessee | 5 | 1 | ||||||

| Green river, Kentucky | 1 | |||||||

| Northeastern Kentucky | 1 | 2 | ||||||

| Northeastern Arkansas | ||||||||

| Kanawha valley, West Virginia | 4 | 4 | 3 | 1 | ||||

| Crawford county, Wisconsin | 1 | |||||||

| Southwestern Illinois | 2 | 1 | ||||||

| Savannah, Georgia | 3 | 2 | 2 | |||||

| Western Tennessee | 2 | |||||||

|

KEY: A = Porphyry. B = Sienite. C = Granite. D = Argillite. E = Greenstone. F = Sandstone. G = Diorite. H = Compact quartzite. |

||||||||

76

D. Of the form last described, except in being much thinner; some have the tops battered, showing use as wedges; length from 3 to 9 inches.

| District. | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Eastern Tennessee | 11 | 3 | 2 | 1 | 1 | 1 | ||||

| Kanawha valley, West Virginia | 2 | 5 | 2 | 6 | ||||||

| Northwestern Georgia | 3 | 1 | ||||||||

| Savannah, Georgia | 2 | |||||||||

| Green river, Kentucky | 1 | |||||||||

| Northeastern Kentucky | 2 | |||||||||

| Southeastern Arkansas | 1 | |||||||||

| Central Arkansas | 1 | |||||||||

| Northeastern Arkansas | 1 | 1 | ||||||||

| Butler county, Ohio | 2 | |||||||||

| Northwestern North Carolina | 8 | 2 | 1 | 4 | ||||||

|

KEY: A = Argillite. B = Porphyry. C = Sienite. D = Diorite. E = Sandstone. F = Granite. G = Hornblende. H = Greenstone. I = Serpentine. J = Compact quartzite. |

||||||||||

Fig. 52.—Celt, showing nearly diamond section.

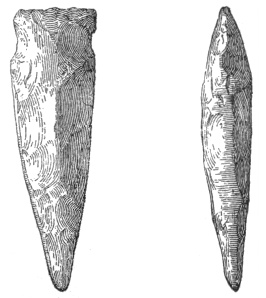

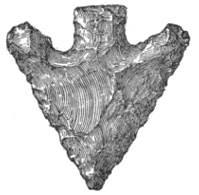

E. Pointed oval, or nearly diamond section, sides straight or slightly curved; length 6 to 12½ inches. Few as these are, they vary considerably in appearance. The group is illustrated by figure 52, showing a specimen of brown flint, containing numerous small deposits of chalcedony, from Benton county, Tennessee; polished over the entire surface, the edge highly so.

In addition, there are the following examples: From Caldwell county, North Carolina, one of porphyry and one of granite, the latter roughened on sides for handle; from McMinn county, Tennessee, one of gray flint, highly polished over its surface, except the top, which is much battered; from Cocke county, Tennessee, one of argillite.

F. Elliptical section, flattened or rounded top, edge curved or nearly straight, sides straight or gently curved, tapering from edge to top or in a few cases nearly parallel. These present many variations in finish and in evidence of use. Some are well polished over the entire surface; some have only the lower part polished; while some are entirely without polish except at the extreme edge. In some the top is battered; some have the surface roughened for handle at the top, others around the middle, still others all over the upper half or even more than half. One from McMinn county, Tennessee, has a roughly pecked shallow groove at the middle. Several have the edge 77 very blunt, the faces at the edge form almost a right angle; these are thickest very near the edge and become gradually thinner toward the top. Most of this kind are from Caldwell county, North Carolina; the same form coming also from Monroe county, Tennessee, and from Savannah, Georgia. The length is from 3 to 7½ inches. Figure 53, of compact quartzite, from Monroe county, Tennessee; figure 54, of granite; and figure 55, of sienite, from Caldwell county, North Carolina.

Fig. 53.—Celt.

Fig. 54.—Celt.

Fig. 55.—Celt.

| District. | A | B | C | D | E | F | G | H | I | J | K | L |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Eastern Tennessee | 4 | 4 | 20 | 7 | 4 | 1 | 1 | |||||

| Western North Carolina | 1 | 4 | 22 | 4 | 3 | 5 | ||||||

| Montgomery county, N. C. | 1 | |||||||||||

| Coosa district, Alabama | 2 | |||||||||||

| Southwestern Illinois | 1 | 7 | ||||||||||

| Kanawha valley, W. Va. | 3 | 7 | 5 | 10 | 1 | 1 | ||||||

| Keokuk, Iowa | 1 | |||||||||||

| Southwestern Wisconsin | 1 | 1 | ||||||||||

| Miami valley, Ohio | 2 | 3 | ||||||||||

| Northeastern Arkansas | 1 | 1 | 2 | 2 | ||||||||

| Southeastern Arkansas | 1 | |||||||||||

| Northwestern Georgia | 1 | 2 | ||||||||||

| Savannah, Georgia | 2 | 2 | 1 | 7 | ||||||||

| Yazoo county, Mississippi | 5 | 2 | ||||||||||

|

KEY: A = Hornblende. B = Serpentine. C = Compact quartzite. D = Argillite. E = Sienite. F = Porphyry. G = Granite. H = Micaceous sandstone. I = Diorite. J = Greenstone. K = Sandstone. L = Flint. |

||||||||||||

78

G. Of the same general pattern as the last, except that the sides widen just before reaching the edge, giving a “bell shape” (figure 56). The length is from 6¼ to 8 inches. In this group there are two specimens of granite, two of porphyry, and one of sienite, all from Yazoo county, Mississippi. Two have their tops roughened.

Fig. 56.—Celt, showing “bell shape” and roughening for handle.

Fig. 57.—Celt, showing rectangular section.

H. Rectangular section, occasionally with the corners sufficiently rounded to give a somewhat elliptical section; top flattened or rounded; sides straight and parallel or nearly so, sometimes very slightly curved. Most have polished surfaces; only three or four show any battering, or roughening for handle. A large one of hornblende from Lauderdale county, Tennessee, has the edge dulled and polished by use. Length is from 2 to 9 inches. Figure 57, of argillite, from a mound in Monroe county, Tennessee. The distribution of this class of celts is wide, as shown by the following table:

| District. | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Eastern Tennessee | 10 | 10 | 2 | 1 | 1 | |||||

| Western Tennessee | 1 | |||||||||

| Northeastern Kentucky | 1 | 1 | 1 | 1 | 1 | |||||

| Green River, Kentucky | 1 | |||||||||

| Southwestern Illinois | 2 | 1 | ||||||||

| Miami valley, Ohio | 2 | 2 | 1 | 1 | ||||||

| Kanawha valley, W. V. | 1 | 8 | 4 | 4 | 1 | |||||

| Northwestern Georgia | 1 | |||||||||

| Savannah, Georgia | 1 | |||||||||

| Central Arkansas | 1 | |||||||||

| Northwestern North Carolina | 1 | |||||||||

|

KEY: A = Sandstone. B = Argillite. C = Porphyry. D = Granite. E = Sienite. F = Diorite. G = Hornblende. H = Limestone. I = Jasper. J = Serpentine. |

||||||||||

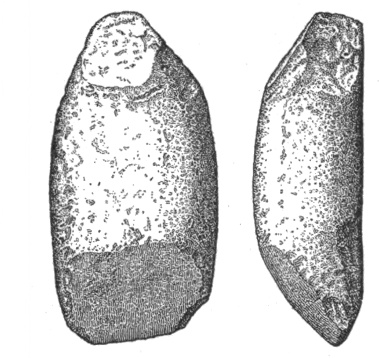

I. Thickest at top (wedge form), section elliptical or nearly rectangular; sides straight or curved, widest at edge or nearly parallel. A few are roughened for handling, and one or two are battered at top by hammering; most are small. The type is shown in figure 58, of granite, 79 from Carroll county, Indiana. This class of celts also is widely distributed and diverse in material.

| District. | A | B | C | D | E | F | G | H | I | J |

|---|---|---|---|---|---|---|---|---|---|---|

| Eastern Tennessee | 3 | 4 | 1 | |||||||

| Northeastern Arkansas | 1 | 1 | ||||||||

| Southeastern Arkansas | 1 | 1 | ||||||||

| Butler county, Ohio | 1 | |||||||||

| Green river, Kentucky | 1 | |||||||||

| Northeastern Kentucky | 3 | 1 | 1 | |||||||

| Crawford county, Wis. | 1 | |||||||||

| Southwestern Illinois | 3 | 1 | ||||||||

| Savannah, Georgia | 2 | |||||||||

| Kanawha valley, West Virginia | 1 | 7 | 5 | 1 | 5 | 2 | ||||

|

KEY: A = Hornblende. B = Granite. C = Sienite. D = Comp. quartzite. E = Argillite. F = Greenstone. G = Sandstone. H = Diorite. I = Porphyry. J = Basalt. |

||||||||||

Fig. 58.—Celt, showing wedge-shape.

Fig. 59.—Celt, showing half-elliptical section.

J. Flat on one side, convex on the other, giving a semi-elliptical section; sides nearly parallel; top flat or rounded. These were evidently intended for scrapers; none are at all chipped or battered from use, and with very few exceptions the whole surface is highly polished. The flint and jasper specimens, which have been first chipped into shape, have the facets and edge as smooth as though finished on an emery 80 wheel. Similar forms, except with flat instead of convex upper surfaces, are known to have been used as adzes, but these have no marks of such use. The length ranges from 2 to 8 inches, but most are small. The type is shown in figure 59, of brown flint, from a grave in Alexander county, Illinois.

| District. | A | B | C | D | E | F | G | H |

|---|---|---|---|---|---|---|---|---|

| Eastern Tennessee | 4 | 1 | 1 | |||||

| Central Arkansas | 1 | |||||||

| Northeastern Arkansas | 4 | 1 | ||||||

| Southeastern Arkansas | 1 | |||||||

| Southwestern Illinois | 1 | |||||||

| Butler county, Ohio | 1 | |||||||

| Northeastern Kentucky | 2 | |||||||

| Tuscaloosa district, Alabama | 1 | |||||||

| Northwestern North Carolina | 1 | 2 | 1 | |||||

|

KEY: A = Graphite. B = Argillite. C = Porphyry. D = Compt. quartzite. E = Yellow jasper. F = Gray jasper. G = Novaculite. H = Sienite. |

||||||||

K. Similar to last, except that the sides come to a point at the top; length, 3½ to 9 inches. Very few of either pattern are above 5 inches long, the larger ones being mostly of flint (figure 60, of sienite, from Warren county, Ohio).

| District. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Northeastern Arkansas | 2 | |||||

| Western Tennessee | 1 | |||||

| Eastern Tennessee | 1 | 2 | 5 | |||

| Kanawha valley, West Virginia | 1 | |||||

| Southwestern Illinois | 2 | 1 | ||||

| Warren county, Ohio | 2 | |||||

|

KEY: A = Yellow jasper. B = Sienite. C = Diorite. D = Gray jasper. E = Argillite. F = Compt. quartzite. |

||||||

L. Sides concave, top narrow. Nearly every specimen has the upper portion pecked rough; one from Bradley county, Tennessee, and another from Mississippi county, Arkansas, are entirely polished. The latter has the scraper-form edge to be described later and is of exceptionally large size; it measures 5½ inches, being the only one exceeding 5 inches in length.

M. Top flat, round, or pointed; the blade usually begins a little below the middle, and is perfectly smooth in every case; in some the blade is not over an inch in length, probably reduced by continual sharpening. They may have been scrapers, though they do not have that form; if 81 used as weapons they were probably set into the end of a piece of antler, which, in turn, was set in a club. The type is shown in figure 61, of argillite, from Monroe county, Tennessee.

| District. | A | B | C | D | E |

|---|---|---|---|---|---|

| Eastern Tennessee | 7 | 1 | 2 | ||

| Kanawha valley, West Virginia | 1 | 1 | |||

| Northeastern Arkansas | 1 | 1 | |||

| Southeastern Arkansas | 1 | ||||

| Southwestern Illinois | 1 | 2 | |||

|

KEY: A = Argillite. B = Sienite. C = Granite. D = Quartzite. E = Hornblende. |

|||||

Fig. 60.—Celt showing half-elliptical section.

Fig. 61.—Celt, showing concave sides.

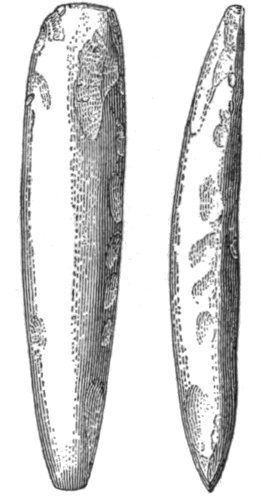

N. Ground down thin, with a flat-elliptical or nearly rectangular section; sides straight or slightly curved, nearly parallel or tapering considerably to the top, which is either rounded or flattened. All are polished over the entire surface; none show any marks of use as wedges or hatchets, and most of them are too delicate for such use. The longer ones can be readily grasped in the hand, and are as well adapted to stripping off the hide of an animal, dividing the skeleton at the joints, or stripping the flesh from the bones, as anything made of stone can be; while the smaller ones, set in a handle to afford a grip, would answer the same purpose. There are three which are sharp at both ends, one having one symmetrical and one scraper-form edge; one having a scraper-form edge at each end on opposite sides; and one of rather soft argillite, unfinished, which has marks of pecking, chipping, and grinding, showing that any of these methods were practiced, as was most convenient. All these are from eastern Tennessee. The features are illustrated in 82 figures 62, of argillite, from a mound, Caldwell county, North Carolina; 63, of black flinty slate, very hard, from a mound, Poinsett county, Arkansas; and 64, of argillite, from a mound, Monroe county, Tennessee.

| District. | A | B | C | D | E | F | G | H | I | J | K | L | M |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Northwestern North Carolina | 2 | 2 | 1 | ||||||||||

| Montgomery county, North Carolina | 1 | ||||||||||||

| Eastern Tennessee | 1 | 53 | 5 | 1 | 4 | 7 | 2 | ||||||

| Western Tennessee | 1 | ||||||||||||

| Northwestern Georgia | 1 | 1 | |||||||||||

| Savannah, Georgia | 2 | 1 | 1 | 1 | |||||||||

| Union county, Mississippi | 1 | ||||||||||||

| Butler county, Ohio | 1 | ||||||||||||

| Northeastern Arkansas | 1 | 1 | 1 | 1 | |||||||||

| Southeastern Arkansas | 1 | ||||||||||||

| Kanawha valley, West Virginia | 2 | 6 | 2 | 2 | 1 | 1 | |||||||

| Northeastern Kentucky | 1 | 1 | 1 | ||||||||||

| Green river, Kentucky | 1 | ||||||||||||

| Coosa district, Alabama | 1 | 1 | 1 | ||||||||||

|

KEY: A = Marble. B = Argillite. C = Sienite. D = Quartzite. E = Serpentine. F = Diorite. G = Porphyry. H = Granite. I = Sandstone. J = Hornblende. K = Compact quartzite. L = Slate. M = Chert. |

|||||||||||||

Fig. 62.—Thin polished celt.

Fig. 63.—Thin polished celt.

Fig. 64.—Thin polished celt.

While there are perhaps no true gouges in the collection, there are some examples of a form between a celt and a gouge, illustrated in figure 65, of serpentine, from Caldwell county, North Carolina.

Implements of this form are known to have been used to tap sugar maples, and also to hollow out wooden troughs, and are very common 83 in the north, though less abundant in the south.20 It is in those localities in which bark instead of logs was used for canoes that they are most numerous. Sometimes they were hollowed the whole length and used as spiles.21 They were also employed instead of celts in hollowing wooden mortars and the like when a more regular concavity was desired.22

The aboriginal implements known as “chisels” are round, elliptical, or rectangular in section. The flint and jasper specimens are generally widest at the edge, the reverse being usually the case with those of other material. Most of them have marks of hammers at the blunt end, though some are polished at the top and a few, from eastern Tennessee, are sharp at both ends. The top (except in the double-edged ones) is usually flat, though a few are pointed or very thin, almost with cutting edges. Jaspers and flints are chipped, with the facets polished, the edges highly so. Any form may occur in any locality. Almost invariably they have scraper-form edges. The length is from 2 to 6 inches.

Fig. 65.—Celt, showing thin, gouge-form edge.

Typical examples are shown in figure 66, of yellow jasper, from a grave in Mississippi county, Arkansas; figure 67, of novaculite, from an unknown locality in Arkansas; figure 68, of serpentine, from Bradley county, Tennessee; figure 69, of sienite, from Caldwell county, North Carolina; and figure 70, of gray jasper, from Bradley county, Tennessee. Some specimens are sharp and worn at both ends, and could have been used only with handles.

Fig. 66.—Celt, chisel-form.

Fig. 67.—Celt, chisel-form.

Fig. 68.—Celt, chisel-form.

84

The Bureau collection includes the following specimens:

| District. | A | B | C | D | E | F | G | H | I | J | K | L | M | N | O | P | Q |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Northwestern North Carolina | 1 | 2 | 1 | ||||||||||||||

| Northeastern Arkansas | 32 | 5 | 2 | 4 | 1 | 1 | 1 | ||||||||||

| Southeastern Arkansas | 1 | 2 | 3 | ||||||||||||||

| Coosa district,Alabama | 1 | 1 | |||||||||||||||

| Warren county, Ohio | 1 | ||||||||||||||||

| Southwestern Illinois | 2 | 1 | |||||||||||||||

| Eastern Tennessee | 40 | 1 | 2 | 1 | 3 | 1 | |||||||||||

| Union county, Mississippi | 1 | ||||||||||||||||

| Kanawha valley, West Virginia | 5 | ||||||||||||||||

| Northwestern Georgia | 1 | ||||||||||||||||

| Savannah, Georgia | 1 | ||||||||||||||||

|

KEY: A = White flint. B = Serpentine. C = Sienite. D = Argillite. E = Granite. F = Yellow jasper. G = Gray jasper. H = Mottled jasper. I = Red jasper. J = Silicified wood. K = Quartzite. L = Black flint. M = Novaculite. N = Compact quartzite. O = Porphyry. P = Sandstone. Q = Hornblende. |

|||||||||||||||||

The high polish sometimes found on the top of a round-pointed celt may be due to its working slightly in the socket in its handle of wood, deerhorn, or other material.

Fig. 69.—Celt, chisel-form.

Fig. 70.—Celt, chisel-form.

By celts having a scraper-form edge is meant those having the edge to one side of the median line, due to constant use of one face. This face, at the edge, is in a straight line from side to side; it may have a chisel-like flattening, or may curve toward the middle of the celt for a short distance and then have the same form to the top as the other face, which is convex or curved, as in the ordinary hatchet-celt. They form a medium between celts whose faces gradually curve from top to edge, and the celt-scrapers which are flat on one side. Among the thicker celts this form is quite rare, though several, especially one from Kanawha valley, West Virginia (represented in figure 74), are quite pronounced. In the thinner specimens, however, a majority are of this pattern, while in some types, nearly all indeed, even those up to 6 inches long, are so beveled. The type, of which an illustration is shown in figure 71, is of very hard black slate; the same form is presented in figures 66 and 70.

From Bartow county, Georgia, is a scraper made from the edge of a celt which has been broken diagonally across from one face to the other. A stem like that of a spear-head has been formed by chipping away the sides of the part broken, which gives a convenient attachment for a handle; the original edge is unchanged except in the wear which has resulted from its new use. 85

The specimen shown in figure 72 (of argillite, from McMinn county, Tennessee) is introduced on account of its undoubted use as a scraper, and because it is much smaller than some of the chipped flints thus classified, the edge being less than an inch wide; the sides are roughly incurved.

In Bradley county, Tennessee, there were found over 200 specimens of very small, thin, flat, waterworn sandstone pebbles, which were mostly in their natural condition, except that they had one side rubbed to a sharp edge. A few, more slender, were ground to a point. Some of them have a handle chipped out on the side opposite the edge, sometimes with nicks in it, made for attachment to a handle by means of a cord. Most of these specimens are less than 2 inches in length. No suggestion is offered as to their use.

Fig. 71.—Celt, showing scraper-form edge.

Fig. 72.—Scraper.

A granite implement from Union county, Illinois, with nearly rectangular section, slightly curved sides, rounded corners, and high polish over the entire surface, having nearly the same thickness (about an inch) at every part, would seem to be a polishing or rubbing stone. There are, however, one from Warren county, Ohio, and three from Kanawha valley, West Virginia, of almost exactly the same size and pattern, which have had one end ground off to a sharp edge; so the specimen may be only an unfinished celt. One of those from Kanawha valley has had the edge partly broken away, and one face has been pecked considerably in an attempt to restore it for use; but the intention was not carried out. Some celts, not of the scraper pattern, which have the edge to one side of the median line, are perhaps broken or blunted specimens redressed on one side only.

Fig. 73.—Scraper or adze, with projecting ridge.

Fig. 74.—Adze or scraper.

Figure 73 exhibits a specimen of argillite from Carter county, Tennessee, probably an adze or scraper, with a projection to keep the 86 implement from being forced into the handle. The edge is symmetrical, though much striated. The specimen shown in figure 74 (of granite, from Kanawha valley, West Virginia) represents a peculiar form. There are several like it in the collection, all but this one from islands in the Pacific.

On account of their shape and undoubted use, a class of celts, although neither pecked nor ground, is introduced. Many of them resemble, in most respects, the so-called paleolithic implements, though sometimes of better finish. They are made with a rounded top and nearly parallel sides; rudely triangular; or with the sides curved to a point at the top. The edge may be straight or curved, and is usually chipped, though sometimes ground; a few are chisel-shaped. Usually they show no signs of wear; when they do, it is always in the form of a polish at the larger end, or on the exposed facets. One of black flint, 8 inches long, from Kanawha valley, has a scraper-form edge, smoothly polished. Many, even of those scarcely changed from their original form and natural surface, have the edges dulled and polished from use as scrapers or adzes.

Fig. 75.—chipped celt.

Fig. 76.—Chipped celt.

Fig. 77.—Chipped celt.

The collection includes the following examples: 36 of argillite, flint, porphyry, and compact quartzite, from Montgomery county, North Carolina, some with the wider edge sharp (figure 75, of flint); 12 of limestone and flint from Mason county, Kentucky; 70 of argillite, a few with the edges ground, from southeastern Tennessee (figure 76, from McMinn county); over 300 from Kanawha valley, nearly all of black flint, a few being of diorite or quartzite—some are partly polished, or have ground edges (figure 77, of black flint, from a mound).

With the exception of two from Iowa and a few from Preston county, West Virginia, the hematite celts in the collection are from Kanawha valley, and are small, ranging in length from 1 to 2¾ inches, except one 4½ and one 5½ inches. They are illustrated in figures 78, 79, 80, and 81, the last from a mound. Nearly all have been ground directly from the 87 nodule or concretion in which this ore of iron so frequently appears. Occasionally one of homogeneous structure has been chipped into form before grinding, the facets in some cases being rubbed nearly away. Sometimes they have a rectangular outline, but usually the sides taper from the edge to the top by a gradual curve, or are parallel a part of the way and then taper either by a straight or, oftener, by a curved line. The section is rectangular or elliptical.

Fig. 78.—Hematite celt.

These implements were probably used as knives or scrapers, being set into the end of a piece of antler, which may in turn have been set into a larger handle of wood. That some were knives is shown by the edge which is dulled to a flat polished surface extending from side to side; and that many were scrapers is shown by their celt-scraper shape, a half elliptical section, or by the scraper-form edge, seen in the largest specimen. Some, however, have the edge symmetrical, as in the hatchet-celts. One has incurved sides, and is roughened on the sides and on the faces near the top.

Fig. 79.—Hematite celt.

Fig. 80.—Hematite celt.

Fig. 81.—Hematite celt.

The fact of the ordinary conical or bell-shaped, long-cylindrical, or somewhat pear-shaped stones having been used for pestles is so well settled that no confirmatory references are needed. A few citations may be given in regard to certain forms sometimes differently classed, especially some of the discoidal stones to be hereafter described.

According to Stevens, the corn crushers used by the Swiss lake dwellers are spherical; some are flattened on two sides, like an orange, others almost round with depressions on four sides. They are about the size of a man’s fist or rather smaller. The Africans have a piece of quartz or other hard stone as large as half a brick, one side of which is convex, to fit the hollow of a larger stone used as a mortar.23 Evans observes that disks sometimes show marks of use as hammers 88 or pestles;24 one found at Ty Mawr was thick, with a cavity on each face.25 In preparing pemmican, the American Indians are known to have pounded the dried meat to a powder between two stones.26 This gives the impression that any suitable stones may have been used; and the ancient California Indians worked out a round stone as an acorn sheller, modern tribes using any smooth stone.27

Fig. 82.—Handled pestle, with expanding base.

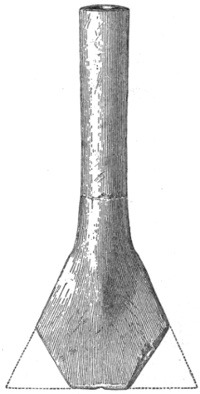

The pestles which have the bottom round or convex are generally found in the same localities as the hollowed stone mortars. Several forms of pestles are represented in the collection. They may be grouped as in the following description and tabulation.

A. With expanding base; bottom flat or slightly convex, often with a slight depression in the middle. Handle tapering, or of uniform diameter to the top; in a few, slightly swelling above as if to give a firmer hold. Top rounded, flat, or pointed. Bottom may be very little expanded or may have twice the diameter of the handle. Probably used for pounding grain or seeds on a flat stone, as it could not be used in a mortar even slightly hollowed. None seem to have been used as mullers or rubbers. They may have served for hammers, and would be excellent for cracking nuts, as the pit in the bottom would tend to keep them from flying out to the side. The type is shown in figure 82, of quartzite, from Sullivan county, Tennessee. The distribution is moderately wide, and the material chiefly granite and quartzite, with a few of other rock varieties, as shown in the table:

| District. | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Northeastern Kentucky | 2 | 2 | 1 | |||

| Eastern Tennessee | 3 | 6 | 1 | |||

| Ross county, Ohio | 2 | 1 | ||||

| Miami valley, Ohio | 1 | 7 | 1 | 2 | ||

| Southwestern Illinois | 1 | |||||

| Kanawha valley, West Virginia | 1 | 1 | 1 | 1 | ||

|

KEY: A = Quartzite. B = Granite C = Sienite D = Diorite. E = Sandstone. F = Argillite. |

||||||

B. Almost cylindrical, from 6 to 18 inches long and about two inches in diameter. Some of the larger ones were probably rolling-pins, as 89 the ends, either from some fancy finish, or because worked to a point, are of a shape that would make their use as pestles impracticable. Even as rollers, some must have been used for crushing grain that had previously been softened or was not fully matured, as they are of a soft stone that would wear very easily. The shorter ones are blunt at the ends, and may have been used in a shallow wooden mortar; none are adapted for use in stone. The class is illustrated by figure 83, of soft clay slate, from Cherokee county, Georgia.

| District. | A | B | C | D | E |

|---|---|---|---|---|---|

| Montgomery county, North Carolina | 1 | ||||

| Northwestern North Carolina | 1 | ||||

| Eastern Tennessee | 3 | 2 | 3 | 1 | |

| Butler county, Ohio | 1 | ||||

| Northwestern Georgia | 1 | 1 | |||

| Hopkins county, Kentucky | 1 | ||||

|

KEY: A = Argillite. B = Soft slate. C = Clay slate. D = Mica-schist. E = Quartzite. |

|||||

Fig. 83.—Pestle, long cylindrical form.

Fig. 84.—Pestle, conical.

C. Conical, or truncated cone, bottom flat, convex or curved from one side to the opposite. Some are quite smooth on the bottom as if from rubbing either back and forth or with a rotary motion; while many have the bottom pecked rough, showing use as hammers or pounders. For those with curved bottoms a rocking motion seems best adapted; with the palm resting on the longer side, good work could be done in any of these ways. Typical specimens are shown in figures 84, of quartzite, from Monroe county, Tennessee; 85, of granite, from Warren county, Ohio; and 86, of quartzite, from Saline county, Arkansas. A somewhat aberrant specimen, shown in figure 87, of granite, from Carter county, Tennessee, has an elliptical base, rounded top, and flat bottom; the longer sides grooved for handle. A similar one, of quartzite, came from Warren county, Ohio. There is considerable variety of material, quartzite largely predominating. Although 90 the geographic range is wide, the distribution is rather sparse, and several districts are not represented.

| District. | A | B | C | D | E | F | G |

|---|---|---|---|---|---|---|---|

| Southeastern Arkansas | 2 | ||||||

| Central Arkansas | 1 | 1 | |||||

| Eastern Tennessee | 12 | 1 | 1 | ||||

| Miami valley, Ohio | 3 | 1 | 3 | 2 | |||

| Montgomery county, North Carolina | 1 | 1 | |||||

| Kanawha valley, West Virginia | 2 | 1 | |||||

|

KEY: A = Quartzite. B = Marble. C = Sienite. D = Hornblende. E = Granite. F = Diorite. G = Sandstone. |

|||||||

Fig. 85.—Pestle.

Fig. 86.—Pestle.

Fig. 87.—Pestle, grooved for handle.

Fig. 88.—Pestle.

D. Conical, or truncated cone, with top more or less rounded, very little worked, a stone of approximate form having been chosen and the angles and corners pecked off; bottom flat, and in some quite smooth; used as pestles or mullers. The group is represented by 17 specimens of quartzite, all from southeastern Tennessee. 91

E. Not dressed at all on the sides, but with both ends worn to a convex shape. Represented by two specimens of quartzite from southeastern Tennessee.

F. Cylindrical, flat bottom, dome-shaped top, these portions having been carefully pecked into shape. Some are smoothly polished on the bottom, but none elsewhere. Those from Miami valley, and one from Kanawha valley are much longer than the others. The type illustrated in figure 88 is of quartzite, from McMinn county, Tennessee.

| District. | A | B | C | D |

|---|---|---|---|---|

| Eastern Tennessee | 5 | 1 | 1 | |

| Kanawha valley, West Virginia | 1 | 3 | ||

| Miami valley, Ohio | 1 | 1 | ||

|

KEY: A = Quartzite. B = Porphyry. C = Sandstone. D = Limestone. |

||||

There is scarcely a locality in the country where pitted stones are not found; they are indeed of such frequent occurrence that they are seldom considered worth the trouble of gathering.

There can be no “type” among such crude implements; they are almost invariably waterworn sandstone pebbles, with a pit varying from a slight roughening of the surface to a hollow half an inch in depth pecked in each face. They probably belong with hammerstones, as they seldom show other marks of work, the edge in some being only slightly marked in one or two places, while in others it is much worn.

Various numbers of the Journal of the Anthropological Society of Great Britain and Ireland refer to pitted stones as found in every part of the world. According to Evans, slight pits aid in holding stone hammers; they also prevent the jar to a large extent. If used to pound meat or break bones, it would be hard to hold them when greasy without pits.28 Such implements may have had handles of wood with projections to fit the pits,29 though this is not probable; but if so a piece of buckskin on the handle opposite the pits would do better and be more convenient to apply.

Conjecture and theory have had full sway in regard to the uses of cupped stones; but the question is apparently far from solution. There is a prevalent idea that they were used for cracking nuts; but why should an Indian make a large number of holes in a great many stones for such purpose? It is true there would be an advantage in having the nut stand on one end; but very few stones have depressions that will allow this.

Of the southern Indians Adair observes:

They gather a number of hiccory-nuts, which they pound with a round stone, upon a stone, thick and hollowed for the purpose. When they are beat fine enough, they 92 mix them with cold water, in a clay basin, where the shells subside. The other part is an oily, tough, thick, white substance ... with which they eat their bread.30

Lawson’s language regarding the Indians of North Carolina is even more definite. He says:

[They gather] likewise hickerie nuts, which they beat betwixt two great stones, then sift them, so thicken their venison broth therewith, the small shells precipitating to the bottom of the pot, whilst the kernel, in the form of flour, mixes it with the liquor, both these nuts [hickory and chinquapin] made into meal makes a curious soup, either with clear water, or in any meat broth.31

Neither of these statements seems to have any reference to cupped stones. The first is a good description of a mortar with a round pestle, while the second says nothing about any particular form of stone; yet they have been referred to time and again as proof of the nut-stone theory. There would be some difficulty in pounding nuts fine in small holes half an inch or more below where the pounding stone could reach.

C. C. Jones32 was satisfied that cupped stones were used for cracking nuts because great numbers of nut-bearing trees grow where they are found; while Whittlesey, noting the fact that hundreds of them are found throughout northern Ohio, considered them as sockets in which the end of a spindle rested. Dawson33 speaks of “stones having deep hollows in the sides which were mortars for grinding pigments, or sockets for fire drills.”

The cupped stones in the Bureau collection are almost invariably of reddish sandstone, of varying texture, from a few ounces to 30 pounds in weight. The holes are from one to twenty-five in number, of various sizes even in the same stone, and follow the natural contour of the surface even when that is quite irregular; the stone is never dressed or flattened to bring the cups on a level; none show any marks of work, but are the rough blocks or slabs in their natural state.

Many of the holes are roughly pecked in, but the larger ones are usually quite smooth, as if ground out, and almost complete hemispheres. They range from a pit only started or going scarcely beyond the surface to one 2 inches in diameter. The smaller ones with one cup pass into the pitted stones. Occasionally at the bottom of a large cup there is a small secondary hole as though made by a flint drill.

The polished cups may have been used for fire-drill or spindle sockets, though why there should be a number of holes when but one could be used at a time awaits explanation. The rough ones may have been for holding nuts, and so long as they were on the same plane any number could be utilized; but when they are on different parts of the stone, even on opposite sides, as many of them are, the question remains open. Slabs or thin pieces nearly always have cups on both sides, while blocks or thick slabs have them on one side only. On the 93 former a number of nuts could be cracked with one blow of a flat stone and thrown into a receptacle of some kind, either side of the stone being used at pleasure; but there would be no economy of time or work in this method, and it would be very strange that any one should not learn with so much experience that a nut should never be laid on the flat side in cracking. No theory yet advanced accounts for the greater number of such relics, namely, the irregular fragments of stone with cups at varying intervals and different levels.

No division can be made in regard either to size or material of the stone, or to form or finish of the cups. Many of the smaller ones were no doubt paint mortars. One well finished specimen of this class is shown in figure 89; it is of quartzite from 4 feet beneath the surface in Crittenden county, Arkansas.

Fig. 89.—Cupped stone or paint cup.

Cupped stones are found wherever representatives of the Bureau have worked, and numerous references might be given concerning their existence in other localities.

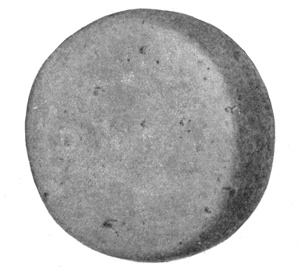

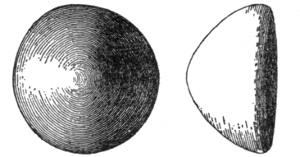

The objects known as mullers are generally flat and smooth on one side and convex on the other, sometimes with a pit in one side or both, mostly of granite, quartzite, or sandstone; rarely of other materials.

A fine specimen of white quartz from Elmore county, Alabama, has the bottom flat and highly polished, the edge perpendicular to bottom and rounding off into the slightly convex top, with a pit at center. Figure 90 represents a muller of marble or crystalline limestone from a grave in Randolph county, Illinois. It has a smooth, flat bottom, with convex top somewhat smaller than the base; around the circumference there is a depression polished by wear. A similar specimen, of diorite, from Carter county, Tennessee, seems to be the lower part of a pestle with expanding base, whose top or handle has been lost, the part remaining having a place for a handle pecked around it.

Fig. 90.—Muller, showing polished surface.

The discoidal stones with this shape were probably used as mullers; they were also used as pestles in the hollow mortars, as the edge is often chipped or pecked, which would account for the pits on the faces. Figure 91 represents a muller of granite from Savannah, Georgia. Sometimes the base has an elliptical instead of a circular outline, as seen in other specimens from Savannah.

Mullers are found wherever there are indications of occupancy for any considerable length of time.

Stones evidently used for grinding and polishing need only to be mentioned, as they are of widespread occurrence. Implements used for the 94 former purpose are made of any siliceous stone of convenient size and suitable texture, from a coarse quartzite to a very fine close-grained sandstone, according to the class of work to be done. The markings on them range from the narrow, sharp, incised lines due to shaping a small ornament, to the broad grooves resulting from grinding an ax or celt into form. Nearly all of those in museums are small specimens used for rubbing; but there are many large blocks in various localities, sometimes several feet square, marked and scored in every direction by grinding or sharpening the large implements on them.