COLLOTYPE

AND

Photo-Lithography

PRACTICALLY ELABORATED BY

DR. JULIUS SCHNAUSS,

Member of the Imperial German Academy of Naturalists, &c.

TRANSLATED, WITH THE AUTHOR’S SANCTION AND ASSISTANCE,

BY

EDWIN C. MIDDLETON.

TOGETHER WITH AN APPENDIX ON

STEAM PRESSES,

BY THE TRANSLATOR.

LONDON:

ILIFFE AND SON, 3, ST. BRIDE STREET, LUDGATE CIRCUS,

1889.

PRINTED BY ILIFFE AND SON, 3, ST. BRIDE STREET, LUDGATE CIRCUS, LONDON, E.C. WORKS: COVENTRY.

| CHAPTER. | PAGE. | |

| I. | Introductory | 9 |

| II. | Bichromates in Conjunction with Organic Substances | 12 |

| III. | Summary of the more important Printing Processes with Chromated Gelatine | 18 |

| IV. | Collotype Apparatus | 25 |

| V. | Chemicals and Materials for Collotype | 46 |

| VI. | Preparation of the Collotype Plate | 59 |

| VII. | Negatives suitable for Collotype | 72 |

| VIII. | Printing in the Press | 88 |

| IX. | Finishing and Varnishing Collotype Prints | 96 |

| X. | Other Collotype Processes | 102 |

| XI. | Failures in Collotype: In the Preparation of the Plates | 107 |

| XII. | Investigations on Collotype | 114 |

| XIII. | Collotype in Natural Colours | 119 |

| XIV. | Magic Prints | 122 |

| XV. | Photo “Glass” Printing | 124 |

| XVI. | Allgeyer’s Collotype Process | 127 |

| XVII. | Practice of Photo-Lithography | 130 |

| XVIII. | Autography | 135 |

| XIX. | Negatives for Photo-Lithography | 149 |

| XX. | Application of the Carbon Process to Photo-Lithography | 155 |

| Appendix. | ||

| Steam Presses | 162 | |

The impossibility of obtaining any work in the English language on the subject of Collotype first led to my translation of the German work of Dr. Schnauss, and the fact that no work has hitherto appeared fully dealing with the matter is the excuse I offer for the present publication. The translation is necessarily one of considerable freedom, but it is offered as containing all the information to be found in the original, and in addition, considerable extensions, made with the author’s consent. The omission of the chapter dealing at length with the steam machine was necessitated by the fact that the rotary machine there described is no longer manufactured.

Without pointing to the frontispiece in any sense as a high-class work, it may serve to show that I have made some practical acquaintance with the subject. The illustration, printed on ordinary paper, was produced from the instructions found in this work, and I may add that at the time of writing I have printed over 500 impressions from the first plate, and it still remains in fair working condition.

EDWIN C. MIDDLETON.

Stanmore Road,

Birmingham.

THE observation by Mungo Ponton of the sensitiveness to light of bichromate of potassium in conjunction with organic substances is but little more recent than the discovery of photography itself. If sized paper is saturated with an aqueous solution of this salt and then exposed under any transparent design, the latter will be reproduced as a negative of a brown colour on a yellow ground. If the exposed paper is placed in water, the bichromate salt will be removed from the unexposed, and consequently unaltered portions; the image will remain brown after this treatment, though somewhat bleached. The sensitiveness to light is proportionately increased by the addition of larger quantities of organic substances, as starch, paste, glue, sugar or gum, as first observed by Becquerel. This arises in consequence of the organic matter being oxidised by the chromic acid, a corresponding decomposition and reduction of the chromate salt to chromate of chromium taking place.

In the year 1853 an Englishman—Fox-Talbot, the gifted discoverer of calotype (i.e., the production of photographic negatives on paper by means of10 silver salts)—followed up the lines of these important observations, and discovered that the mixture of bichromate of potassium and glue entirely lost its solubility and power of swelling in cold water after exposure to light, and on this he based his process (heliography) of etching on metal plates. The plate, after receiving a coating of the chromated gelatine solution, was dried, exposed under a positive, and afterwards developed or washed out in warm water, all unexposed and consequently soluble portions being removed, while the exposed and therefore insoluble portions covered as a negative[A] the metal plate, and so protected it in those parts from the etching mordant employed, usually chloride of potassium or perchloride of iron. His successor in these researches was a Frenchman, Poitevin, who invested these processes with even greater practical importance. He, however, worked chiefly on paper with the bichromate mixed with albumen or gelatine, and attained results which were the first practical steps towards photo-lithography and carbon or pigment printing. Further on we shall return with more detail to these subjects. In the hands of Tessié du Motay and Marechal, of Metz, the discoveries of Poitevin derived further practical value, and to them we are indebted for the first advances in collotype, they in their practice using metal plates as a support. Joseph Albert,11 of Munich, followed, and introduced further and considerable modifications, amongst others utilising glass plates as a foundation. The want of adhesiveness of the chromated gelatine layer to its support was a source of great trouble to the earlier experimentalists, and was a matter giving rise to innumerable difficulties, which were, however, finally surmounted by the researches of Husnik, Albert, and Obernetter.

[A] For the production of an intaglio plate the impression on the chromated gelatine must be printed from a positive, which will naturally give a negative on the copper plate.

CHROMIC Acid, now usually known as chromium-trioxide—CrO3—is found in beautiful red needles, which are slightly deliquescent. According to the present accepted theory, water containing such crystals in solution contains the true chromic acid, H2CrO4, which cannot be produced as crystals. Both the crystals and a concentrated solution in water give up with facility a part of their oxygen, sometimes with explosions accompanied by the appearance of fire, and green chromium oxide, now called sesquioxide, Cr2O3, is formed. Bichromates of alkalies act in a similar manner, but in a lesser degree. If, for instance, a few drops of sulphuric acid be added to a solution of potassium bichromate, and then a little alcohol, or, instead of that, a piece of sugar be added and moderate heat applied, the solution will be violently agitated, its yellow-red colour will disappear, the bichromate be decomposed, and chromium oxide be formed, which, combining with the sulphuric acid, forms a solution of a violet green colour. If a sufficient quantity of sulphuric acid be present, the chromium sulphate and the potassium sulphate combine, forming chrome13 alum crystals, octahedron in form, similar to those of ordinary alum, but of a beautiful dark violet colour. The same are used in both the carbon and collotype processes. Bichromate of ammonium is easily decomposed by fire by heating it in a dry state. It will be understood that in consequence of the decomposition, or rather reduction, of chromic acid by organic matter, the latter is also decomposed and oxidised in a corresponding degree. The agent producing this effect may be either heat or light, or both together; but of special interest to the collotypist is the action of light upon different combinations of chromic acid, in the shape of alkali bichromates in conjunction with organic matters.

Glue or Gelatine, in a solution containing about five per cent. of one of the bichromates spread upon glass plates, and exposed to light, will, where exposed, become dark brown, at the same time become insoluble in water, and also lose its power of absorbing the same. According to the researches of Dr. Eder, this brown substance consists of chromium chromate and unaltered gelatine. The oxidised portion of the latter remains soluble and may be entirely removed by treating with warm water. During the exposure to light formic acid is undoubtedly formed. Ammonium bichromate, with gelatine, is in the dry state much more sensitive than the potassium salt; it also decomposes more readily when heated in the gelatine solution, a matter which must not be lost sight of in the preparation of the collotype plate.

14 Isinglass—a tolerably pure glutin. In conjunction with the bichromates it presents the same characteristics as gelatine.

Albumen, when mixed with a solution of a bichromate, is not thereby coagulated, as occurs upon the addition of pure chromic acid. If poured upon glass and dried it also becomes insoluble in water after a sufficient exposure to light. This solution is used with great advantage in photo-lithography, as the unexposed parts are readily soluble in cold water. The older method, which consisted of using gelatine in conjunction with bichromate, rendered hot water necessary in the development of the fatty ink image upon the transfer paper, and as a consequence of the rubbing at times necessary, the ink, already softened by the warm water, became smeared, the resulting image considerably impaired, and the transfer thereby rendered altogether useless. In collotype a bichromated albumen substratum is still used by many operators, this coating when dry being exposed through the glass plate, the latter placed coated side downwards upon a flat black support, preferably of velvet. After this exposure the gelatine layer—from which the prints are produced—is applied. This method was first published by Albert, who originated it. The chromated albumen solution will not keep long even in the dark,[B] as the albumen coagulates, and on this15 account photo-lithographic papers coated with this solution must be used within a few hours of their preparation. Such papers are now conveniently prepared with the albumen,[C] and sensitised as required by floating upon an aqueous solution of one of the bichromates, to which has been added twenty-five per cent. of methylated spirit.

[B] I have found this solution keep a considerable time—a month at least.—Trans.

[C] I believe Husnik has now discontinued to prepare his photo-litho transfer paper with an albumen coating. Recent issues of his paper have been simply coated with gelatine.—Trans.

The chromated gelatine used in collotype may be kept as a jelly in the dark room, but is better prepared fresh.

Of carbon hydrates only gum chromate is of interest to the collotypist, its employment being restricted to the “dusting on” process, and the occasional addition of titles, &c., to the otherwise finished plate. As with all mixtures of the bichromates and organic substances, it is only sensitive to light when in a dry condition, and solutions of it may, without harm, be exposed for some time to diffused daylight. Aqueous solutions of gum arabic soon become sour and mouldy, and in this condition are useless for the “dusting on,” or, in fact, any other photographic process. As a preventive a few grains of sulphate of quinine may be added, which will preserve it effectually, and is quite inert in photographic operations.

This solution applied to glass and dried is, in its dry condition, extremely sensitive to light. If printed under a negative, and then exposed to a16 damp atmosphere, it absorbs moisture, and becomes “tacky” upon the portions fully protected by the densest portions of the negative, while the parts exposed under the clear glass of the negative will be free from any such tendency. The gradations of the negative between these two extremes will be represented by the surface of the gum being more or less adhesive, and it is this property which renders it valuable in various processes. After exposure under a negative finely-ground colour—for instance, graphite—is carefully dusted over the surface of the plate by means of a camel-hair brush, and the powder will adhere in exact proportion to the protection afforded by the negative. A picture is thus produced in graphite powder possessing all the gradations of the original. From a negative a second negative is produced, while from an exposure under a positive a positive will result, each, however, reversed as regards left and right when compared with the original. Advantage is taken of this process to produce reversed negatives, a subject more fully dealt with in another chapter.

Bichromate and Sugar are never used alone, but as an addition to heighten the sensitiveness and increase the hygroscopic properties of the gelatine or gum-chromate solutions. By the addition of sugar and a little ammonia to chromated gelatine the solubility of the gelatine in hot water is increased. The addition of acetic acid instead of ammonia acts in a contrary direction. It is advisable to become acquainted with the action of certain substances, the17 application of which to the printed layer increases its solubility after exposure to light, and of others having a contrary or hardening influence on the same, such oft-times proving of service in the case of under or over exposure. To the former class belong all alkalies, as chloride of lime and cyanide of potassium; while among the latter, which have a tanning or hardening effect on gelatine, may be particularly mentioned tannin, alum, chrome alum, and chloride of zinc.

To remove spots, which print dark, from collotype plates a solution of chloride of lime is used. To produce dark spots without exposure to light a solution of tannin is used, which is also available for adding descriptive titles or other matter to the plates. The ink will “take” as well on the spots or parts touched with the tannin solution as if exposed to light. A collotype plate which has been prepared for printing from may also have writing executed upon it with a bichromated gum solution, once more exposed to light, the writing will then readily take the ink, and appear in the impression as a black inscription.

Gum chromated solutions reduced to proper proportions, and applied to different textures and the same subsequently exposed to the light, render them completely waterproof.

THESE processes are all based upon the change in the hygroscopic properties of chromated gelatine brought about by the action of light, which renders the parts exposed insoluble.

Carbon or Pigment Printing.—In this interesting process finely ground colouring matter is added to the solution of chromated gelatine, and spread upon paper; or the paper may be coated with the gelatine and pigment, and afterwards excited by immersion in a solution or bath of one of the bichromates. If, after drying such paper or tissue, it be exposed under a negative in an ordinary printing frame, and then immersed in warm water (90° to 130° F.), the water will dissolve only such portions as may not have been affected or hardened by the action of light through the negative, while the parts that have been exposed to its action will be insoluble, and remain attached to the paper support, forming a positive picture. Images produced in such a manner, however, are devoid of half-tone, and this procedure is only suitable for line subjects, while even for such the paper must have been very evenly19 coated, or portions of the picture may be washed away. For the production of half-tone subjects it is necessary that the picture be developed from the back. This may be effected by transferring the printed tissue, after first soaking in cold water, to a surface, usually either of paper or glass, and developing it in contact with, and allowing it to remain upon, such surface. This procedure is known in carbon printing as single transfer. Unless the negative be a reversed one—or a film printed from the reverse side—the resulting print will be subject to the disadvantage of being reversed as regards left and right. In cases where ordinary negatives have to be used, and this reversal cannot be tolerated, it is overcome by the “double transfer” method of printing, the print in such cases being developed upon a so-called “temporary support,” and again transferred to its “final support,” when it appears as a non-reversed image in permanent pigment.[D]

[D] For further details of this interesting process see the “Autotype Manual,” by J. R. Sawyer; or Liesegang’s “Carbon Process.”

The “Powder” Process.—Take, instead of gelatine, a solution of gum arabic and sugar, to which is added a solution of bichromate of potassium or ammonium. With this a glass plate is coated, dried, and exposed under a negative, if it be desired to produce a negative; or, if a positive be desired, the exposure must be made under a positive. After a short exposure the plate is dusted over with a powder in an extremely fine state of division, such as graphite if for negatives; if for burnt-in enamels, a20 specially-prepared enamel, ground extremely fine, must be used. Such powders will only adhere to the plate in exact proportion to the action of the light during the exposure in the printing frame, and a reversed copy of the original will be produced.

Collotype and Glasstype.[E]—In these processes the printing depends upon the property possessed by the bichromated gelatine film, which has been properly exposed under a negative, of absorbing water in varying proportions, in exact accord with, but in inverse ratio to, the action of the light. The application of a roller charged with fatty ink of a suitable consistency, will deposit upon the gelatine surface a layer of ink in exact proportion to the action of the light and in inverse proportion to the amount of water absorbed by the film. In this manner a picture is produced in ink which by printing is transferred to paper, and will exhibit all—even the finest—gradations of light and shade.

[E] Glasstype, more fully described later on, has never been practised commercially in England.

Woodburytype.—If an especially thick film of gelatine, containing a small proportion of pigment, be sensitised, exposed under a negative, and subjected to prolonged soaking in warm water, a picture exhibiting considerable relief will be obtained, which, after drying, may, by pressing into lead or treated by the galvanoplastic method, yield a matrix from which casts may be produced in a coloured gelatine solution, or ink, which is poured into the mould; on this is placed a waterproof paper; the press, which is21 of special construction, is closed, and the ink allowed to set; the paper is then removed, bearing upon its surface the printed Woodburytype, which is hardened by alum, and then scarcely distinguishable from a silver print.

Stannotype is a modification of the last-described process by the same inventor. A positive is first produced from the original negative, and from the positive a print is made on a thick gelatine tissue. This is developed by long washing in warm water, the resulting relief being a negative; this is coated with tinfoil of extreme thinness, and used as a mould for printing from with the gelatine ink, as previously described. This obviates the use of hydraulic pressure and special and expensive appliances.

Heliogravure; Photogravure.—If, instead of printing from the Woodbury mould in the gelatinous solution, a fatty ink is used, the process is known under these titles. The exact methods of roughing the depths of the plates to facilitate their retention of the ink are regarded as secrets by the most successful operators.

Photo-Lithography and Photo-Zincography.—In dealing with a subject in lines, dots, or stipple, a paper may be coated with a solution of chromated gelatine, dried, exposed under a suitable negative, coated with a film of fatty ink, and allowed to soak in cold or tepid water; this, penetrating the unhardened portions of the film, causes them readily to part with the ink, which, however, adheres22 tenaciously upon the hardened portions, representing the picture. This image, when properly cleared, may be transferred to stone or zinc, and printed from in the lithographic manner upon a suitable press, or if the image upon the zinc be etched into relief by the process known as Gillotage, and mounted on a wood block of suitable height, it presents a printing surface which may be used in conjunction with type.

Gelatinotype.—It has long been felt as a desideratum to make use of the photogenic properties of the gelatino-bichromate for letterpress printing, i.e., to find out a simple and satisfactory method by which collotype plates could be transformed in letterpress printing plates. There have been made many attempts in this direction, but hitherto without any practical results; the difficulties seemed to be too great. Recently, however, Professor J. Husnik, of Prague, has overcome these difficulties, his new patented process, called by him “Leimtypie,” that is to say, Gelatinotype, being one of the greatest practical value, quick, cheap, and giving most satisfactory results. The process consists in the production of high relief blocks in gelatine. Husnik exposes a gelatino-bichromate tissue under a negative, and then develops the relief picture in a peculiar manner.

The method consists in the application of a saturated solution of bichromate salts for developing, a new and previously unknown property of the chrome salts thus coming into employment. These salts, in comparison with the acids, have the advantage not23 only of dissolving all unexposed gelatine during development, but also in hardening the already exposed parts of the picture upon the copy to be developed, the impression received from the light being increased by contact with the chrome salt solutions. In this way the relief can be developed a longer time, and becomes deeper.

Another new phase is the manner of the second development. The first development is interrupted before the fine parts have been injured, the relief allowed to dry, the white parts (the sub-ground) covered with printing ink diluted with turpentine, using a fine brush quite near to the lines, and then the whole relief exposed once more to light. The relief, on account of its having taken up much chrome salt during the first development, is very sensitive to light, and hardens not only on the surface, but also on the sides of the lines. After removal of the black ink it can be developed to any depth, particularly if the larger white parts have before been cut out with a knife.

This process has lately been further improved by the inventor, by the use of gutta-percha films, which are placed between the gelatine film and the zinc plate on which the gelatine relief has to be fastened. This is effected as follows:—The zinc plate, after having been well cleaned and rubbed over with emery paper, is coated with a gutta-percha solution and dried. It is then heated to about 212° F., and allowed to cool. During this cooling process the bichromated gelatine film, before being24 developed, is laid on at a temperature of between 111° and 77° F., whereby the hardening gutta-percha film secures a perfect combination with the zinc plate. When this has been done the gelatine film is developed in the above described manner to a relief. By this improvement the gelatine blocks become so solid that they will yield more than 50,000 prints in the printing machine without being injured.

BEFORE commencing any practical work it will, of course, be necessary to procure various utensils and material not usually found in the photographic studio. All these should be procured from reliable dealers and of the best quality, for the evil consequences of false economy will make themselves felt in endless failures. The best to be obtained are none too good for collotype. In the practice of photography the whole success depends on a series of apparent trifles, and the same may be said to hold good, but in a far greater degree, in this process, which is one in which the difficulties can scarcely be overestimated.

The photographer will most likely be already in possession of many pieces of apparatus he may utilise—for instance, dishes. The best and dearest are those of china; but for many—in fact, most—collotype purposes, those of tin or zinc may be used.

For warming or cooking the gelatine solutions tin vessels are the handiest, as they easily conduct the heat and are unbreakable. Although the chromated gelatine may remain in them for a short period without harm, it is not advisable to allow it to do so for any length of time, but to remove the solution and wash the vessel thoroughly with hot water, and at26 once carefully dry, otherwise they will soon corrode, and contaminate the gelatine solutions. The best utensils to use are wide-mouthed shallow jugs, as they are easily kept clean, and in them the chromated gelatine solution keeps well, and with their use no fear of decomposition need be entertained.

Filtering the gelatine solutions is a somewhat troublesome matter, and should be effected at a high temperature and as quickly as possible. The simplest method is to procure a piece of perfectly clean flannel of suitable size, thoroughly moisten it, and insert into a brass ring, which is provided on the outside with small barbel hooks, to which the flannel is fixed, as in the retinaculum of the chemist. The ring is provided with a clip and handle, by the former of which it may be attached to a vessel of almost any size, and the latter is a convenience in holding it over plates to which the gelatine has to be applied. A careful filtering is obviously essential to the production of clean plates. Many complicated filtering appliances have been devised for gelatine and other solutions difficult of filtration, as, for instance, those of albumen or gum. Baron Szretter describes in the “Photographische Correspondenz,” 1878, an apparatus constructed by him. It consists of two vessels, an upper and a lower one, which by means of longer or shorter tubes communicate with each other in accordance to the stronger or weaker pressure required by the liquid to be filtered. Soldered round the upper rim of the lower vessel is a ring of sheet brass, about two to three cm. in width27; over this ring the filter paper is placed, which again is covered with a piece of strong felt enveloped in flannel. To prevent the liquid escaping round the sides of the ring a strong iron ring is applied, which by means of a screw presses against the felt so that no space exists between the ring and the paper. To prevent the pressure of the liquid forcing the felt out of position, and so tearing the paper, a metal wire gauge is used to keep the felt in place. The liquid placed in the upper vessel passes through the tube into the lower vessel through the paper and felt layer. When it is necessary to warm the solution to be filtered, as in the case of gelatine, the whole apparatus is covered with an outer covering, and on the other side a pipe is applied for the purpose of effecting a circulation of the heated liquid, which is thus kept constantly rising through the one pipe and returning through the other.[F] 28 Heat is sustained at an even temperature during the whole operation by means of a small lamp. A simple method of filtering such solutions is to pass them through purified sheep’s wool, or spun glass, a quantity of which is placed in the tube of the funnel. The whole apparatus may be placed in a warm oven during the process, or the drying box may be utilised for the purpose.

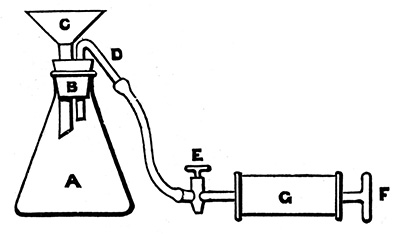

[F] The above description not perhaps being perfectly clear, and having been unable to obtain any further description, I give a sketch (Fig. 1.) of an apparatus found to answer well for the filtration of gelatine solutions and other viscid bodies. is a glass flask, a rubber stopper, a funnel containing a filtering medium of washleather, a tube attached to a three-way cock ; one hand manipulates the latter, while the other works the piston of a syringe .—Trans.

Printing Frames of different sizes will be found to hand in the photographic studio, and may be utilised without alteration for printing the collotype plates, if they are deep and strong enough to bear the necessary pressure, which is usually applied through the medium of springs; these are better removed, and wooden wedges inserted in their stead between the cross-bars and the loose wooden back of the frames, as by these means far more pressure may be applied. By lifting the one half of the hinged back of the printing frame an examination by transmitted light of the collotype plate may be made and an experienced operator will in this manner judge the exposure of the plate.

The Actinometer is, however, recommended, particularly for a beginner, as it greatly aids in forming a correct idea of the exposure.

The Drying Box is of great importance to the successful working of the process. The opinions of the various practitioners with regard to the temperature at which the drying of the plates should be effected differ as widely as upon the advisability or29 otherwise of admitting a current of air through the box during the operation. The drying should be completed as rapidly as possible from the commencement of the operation, care being taken that the heat never exceeds 50°C. Many plate-makers simply dry the plates in an open apartment—of course, only illuminated by a non-actinic light—simply placing the plates on a horizontal surface, which may be maintained at the temperature indicated by a water bath, a lithographic stone, or merely a cast-iron plate arranged in a suitable manner for heating from below. This method of drying is open to many objections: the surface of the plate is seldom free from dust, and the gelatine coating is too liable to irregularities from draughts admitted to the apartment during the process. They are more frequently dried in specially-constructed boxes provided with screws for accurately levelling the plates, and through which only a small circulation of air takes place. These boxes are usually rectangular in shape, the upright sides being of wood and the bottom of sheet iron. The lid is an open framework covered with a close orange or black cotton material, the whole standing upon four iron legs over a spirit or gas flame. In the upper part of the box a thermometer is fixed, about the centre of either the side or lid, in such a position that it may be readily observed without the necessity of opening the box. Strong horizontal iron bars are placed across at about the centre, and are provided with30 thumbscrews, upon which may be placed a plate of glass bearing a circular spirit level, by which means the plates may be levelled with the greatest accuracy. The sheet-iron bottom of the box being heated unevenly, it becomes necessary to mitigate this inconvenience as far as possible, which is easily done by covering the plate to a depth of about half-an-inch with dry river sand, over which should be placed tissue paper to keep down any possible dust.

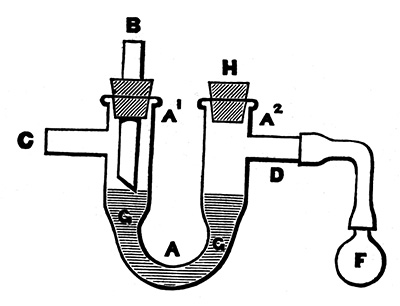

An Automatic Regulator of practical value is that devised by Ruegheimer. It consists of a glass tube, , , . is closed with an indiarubber stopper, through which passes a glass tube , the lower end of which is cut off at an angle. It is attached to the gas supply pipe. The tube is connected to the burners. To is attached, by means of rubber tubing, a glass bulb , which is placed inside the drying-box. is mercury, and a rubber stopper by which the pressure on the mercury and quantity of air in may be regulated.31 The action of the instrument is obvious. The gas passes down , over the surface of the mercury and by the tube to the burner. On the bulb reaching a certain temperature, the mercury will allow just sufficient gas to pass from the tube to maintain the box at a given heat. If it should fall, the mercury recedes from the aperture of the tube , a larger quantity of gas passes to the burner, and the temperature is restored to a normal degree. If the air in the ball expands to too great an extent, the mercury rises, and would eventually entirely close the aperture and cut off the gas supply, unless the tube is provided with a small hole acting as a by-pass. The tube may be moved up and down through the rubber stopper at as a means of adjustment.

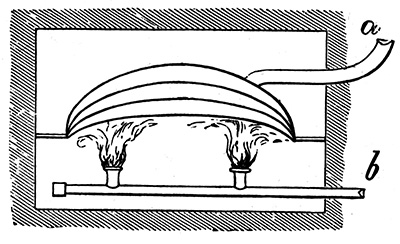

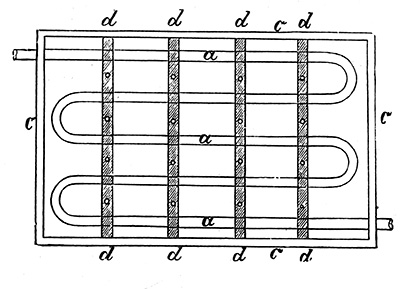

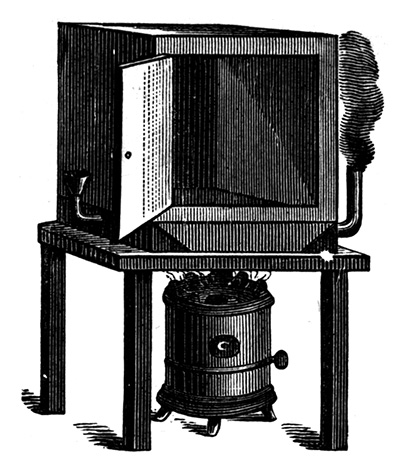

M. Thiel, of Paris, uses a very convenient drying-box, which, with his permission, is here explained. In a brick-lined receptacle under the laboratory floor lies the water-heating apparatus, which is constructed of sheet copper, and is capable of containing about four litres of water, utilised in the production of steam for heating the box. a, fig. 3, is the pipe passing through the wall into the32 drying-box; b is the gas supply pipe to the two atmospheric burners. Fig. 4 represents a plan of the drying-box; c c c c the perpendicular sides of the same, a a a gives a plan and position and arrangement of the earthenware heating pipes lying in a serpentine form at the bottom of the box, entirely covered with dry sand, and this again covered, as before described, with tissue paper. b is the outlet of the steam pipe. d d d d are movable horizontal iron bars with adjusting screws, on which the plates are levelled. The box is covered by a hinged lid, which is raised about a couple of inches during the drying to allow the air to circulate. The dimensions of the box will be determined by the size of the plates to be used, several of which may be placed side by side. Its height is about half a metre inside, and the plates are placed about its centre.

Glass Plates, to be used for printing from, must as a first consideration have their surfaces33 ground quite true and parallel. Since the introduction of special collotype presses requiring less pressure, the thickness is of less consequence than formerly, but for convenience of handling and to withstand the necessary pressure, in the printing frames, plates of at least four millimetres in thickness are desirable. Many use them from 8 to 10 millimetres in thickness; this, in the larger sizes, means a weight both inconvenient and difficult to handle. It is probably easier to work upon plain glass surfaces, and since means have been discovered of causing the chromated gelatine to adhere to polished glass with sufficient tenacity to produce several hundred impressions, the employment of ground glass plates is much more a matter of choice than formerly. The ground surface, however, assists the formation of a grain in the case of thin layers, and the operation of grinding serves to remove accidental scratches from the surface of the plates. As in practice these damages constantly arise, it will in the long run be found both desirable and economical to employ the ground plates.

Ink Rollers are also of great consequence in both collotype and lithographic operations. For printing from stone leather rollers have always been exclusively employed, and they are still used in some collotype establishments, more particularly where hand presses are yet worked.

The Leather Roller consists of a wooden cylinder or stock of about 21 to 42 cm. in length and34 9 to 11 cm. in diameter, with handles at either end, usually turned in one piece with the cylinder. Boxwood handles are sometimes let into the ends of the cylinder, but although smoother to work, they not infrequently work loose. In using these rollers the handles do not come in direct contact with the hands, but are covered with a protection of stout leather, which not only protects the printer’s hands from heating, but enables him by a heavier or lighter grip of the handles to apply a heavier or lighter pressure of the roller—a point of great value in inking the plate.

The wooden stock of the roller is first covered with a double thickness of woollen material—flannel or Melton cloth—and over this is drawn the cover of calf-skin, flesh side outwards. The manipulation of the seam must be managed with extreme care, as any unevenness would render the roller useless. At both ends of the cylinder the leather projects, and is usually drawn tight with string or nailed on. There are two descriptions of leather rollers—smooth and coarse. The latter are only used to apply ink to the stone or plate, and then, with the smooth roller, the proper distribution of the ink is effected. For the latter purpose, in collotype, hard glue or indiarubber rollers are employed, being considered far preferable. When a leather roller is in good order, and its use has been thoroughly mastered, it is looked upon by many printers as indispensable. A serious disadvantage is that when new they are35 almost unusable for collotype, and after prolonged use the leather stretches, they become wrinkled, and this, of course, affects the even distribution of the ink. A new leather roller needs a special preparation or “breaking in” before it may be considered fit for use. It should be well saturated with a fatty matter, a very effectual way of doing which is to roll it well at intervals in a moderate supply of thin varnish as used for thinning printing ink, this process being persevered with so long as the roller continues capable of absorption. A better but more troublesome method is to roll the rollers twice daily in thin varnish, continuing the operation for a week, at the end of which time the roller may be well rolled upon the inking slab in stiff black printing ink, the superfluous ink being occasionally removed from both the roller and slab by scraping with a blunt knife, and a fresh supply of ink applied. This troublesome and tedious operation should be continued for a period extending over several weeks until it has become quite smooth and even, though it will still be found better to use it only for common work, or, if possible, on stone. To keep the roller in good condition it should, on each occasion after use, be carefully scraped with a clean, smooth-edged knife—not too sharp. Some practice in this operation is required to avoid cutting the leather. Great care should be taken to avoid this, the blade of the knife being held almost flat upon the roller during the process. The scraping should always be in one36 direction, to ensure which it is advisable to place a mark upon one of the handles.

Unless these precautions be observed the ink will dry in, and completely spoil the leather. If not to be used again for some time tallow should be carefully and thoroughly rubbed into the surface of the roller as a preservative, but before again using this coating must be removed either by means of a knife or washing with turpentine.

Glue Rollers have long been in use, but chiefly for letterpress work and steam machines in general. A soft composition of a very elastic nature is quite useless for collotype; its substance must, on the contrary, be tolerably hard, and of a brown colour, as usually employed on the steam letterpress jobbing machines. For hand rollers for collotype it is preferable to have a strong iron frame with double handles, as used by letterpress printers. Such rollers are preferable to those of leather, and will answer perfectly for laying on the first stiff ink, and also for rolling up the half-tones. To clean they should on no account be scraped, but simply washed with turpentine, and on this account are much easier cleaned than leather rollers. Schaarwächter gives the following as an excellent composition for collotype rollers: Brown glue, three parts, steeped for two days in cold water. The pieces should then be dried in a cloth, and afterwards dissolved. When melted add, with constant stirring, one part of treacle, which has been previously boiled, allow the whole to boil,37 and skim. The composition is then run into a thin copper cylinder or mould, which must be polished smooth, clean, and well oiled; and in the centre of which has been placed the wooden cylinder or stock. After cooling, the roller is pushed out of the mould, and washed with alcohol or turpentine to remove any trace of greasiness due to oiling the mould, placed in a bath of tannic acid, washed with water, and dried. The composition rollers, as used in typographic printing, are made with glycerine instead of treacle, and may be used for collotype if not too soft.

Indiarubber Rollers are more expensive, but possess special properties rendering them particularly suitable for photo-lithography. In construction a wooden stock with suitable handles is covered with very thick well-vulcanised indiarubber, which has a fine smooth surface, rendering it easy to clean by means of turpentine. If it becomes “tacky” on the surface it should be well rubbed with French chalk, or soap-stone, which will readily absorb the turpentine, but this coating must be thoroughly removed before again using the roller. An excellent suggestion appeared in one of the polytechnical periodicals, that the rollers should before use be coated with a solution of pure or bottle rubber in benzole or bisulphide of carbon after having been well washed with turpentine.

These indiarubber rollers are not suited for the first inking of the plate, but are invaluable for rolling up the half-tints of the collotype plate. As they38 somewhat readily take colour off the plate they must be first rolled up in a thinner ink and a separate slab. According to “Lithographia” these indiarubber rollers may be cleaned with lye, or strong alcoholic spirit. If cleaned with turpentine it may be advantageously followed by rinsing with soap and water; by so doing the application of French chalk is unnecessary. These rollers are, by comparison with others, nearly indestructible, and therefore cheap, notwithstanding their high first cost.

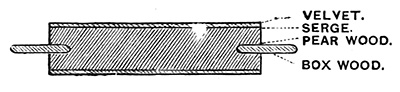

Velvet Rollers have latterly come much into use, and are very successfully used for inking-up the transfers in photo-lithography. They may be also used in photo-xylography and photo-ceramic processes, and also for certain purposes in collotype. A necessary precaution is that the seam of the velvet should always be kept off the surface subjected to the rolling, and this may be carried out if the roller is, say, 10-1/2 centimetres in diameter, a length of 31·2 centimetres may then be rolled without using the seam. The sketch will explain the construction. The cylinder or stock is of pear-wood, and the handles of box; first covering serge, which before sewing on should be well shrunk in hot water; over this comes the velvet, the edges of which must not overlap, but must be drawn together as close as39 possible by means of thread. One advantage of this roller is that it is ready for immediate use; it must, after use, be carefully cleaned before being placed aside; this is best done by repeated rollings on a clean slab, and the judicious application of a little turpentine. Turpentine only may be used to thin ink for use with this roller.

Drying Rollers.—In addition to those already enumerated, all of which are intended for the application of the ink to the plate, other rollers are required, similar in construction, but covered with wash-leather or cloth, and used for the purpose of absorbing superfluous moisture. For these it is necessary, or at least advisable, that the frames be so constructed that the rollers may be readily removed when by continued use they have become too damp. This method of drying the plates is far preferable to the customary one of wiping with a cloth, for even with the greatest care, if the printing should extend over hundreds of copies, the layer upon the plate will inevitably get scratched when wiping or rubbing is resorted to, especially if isinglass—which tends to soften the film—be present.

Palette Knife or Spatula.—It is unnecessary to describe; they are used for mixing the ink and applying it to the slab and rollers, and for cleaning the latter. They may be either of hard wood or metal.

The Ink Slab may be either of slate, a lithographic stone, or a sheet of strong zinc securely attached to a block of wood truly planed.

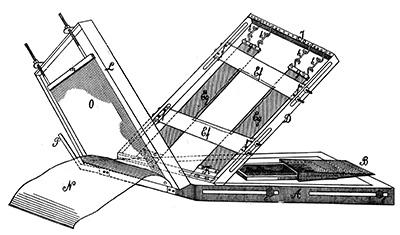

40 The Press is an indispensable requisite for printing operations. There are small wooden hand-presses, especially constructed for collotype, which may be purchased at a very low price—£4 to £5; but the more economical way is to procure a small lithographic press constructed of iron. This will not only be found more durable, but it may, if occasion arise, be used either for lithographic or zincographic printing, as it will bear the necessary pressure, which is greatly in excess of that applied in collotype printing. The hand-press constructed by Sutter is a form that may be strongly recommended. If the output of prints is to be large, a steam machine will be necessary, the cost of which will be not less than £200 to £250. Fig. 6 represents a press which has been largely used for collotype. is the bed or carriage upon which the plate is fixed in the manner described further on. By turning the crank handle the bed is carried under the scraper, which is secured in the scraper-box . The scraper is kept in position by the lever . The scraper-box is represented as closed down in the illustration, but in actual practice it would not be in the position shown until the tympan-frame had been lowered.

The Tympan, of either leather or thin sheet zinc or brass, is marked in the illustration. All iron portions of the press subject to friction should be frequently cleaned and carefully oiled with a good machine-oil.

The Scrapers should be of either pear tree, lime, maple, or preferably box, with a blunt bottom edge, which should be planed true, and finally finished by rubbing on a sheet of glass-paper placed upon a perfectly flat surface. They must be adjusted with even more precision than is necessary in lithography, as owing to the difference in the printing surface, the same pressure cannot with safety be applied. With plates or stones of large size it will be found that the pressure of the scraper will be unequal, greater pressure being42 exerted in the centre than upon the edges of the printing surface. Many printers, to counteract this tendency, slightly scrape away or hollow out by means of a piece of glass the centre of the scraper. With sufficient pressure and plenty of elastic packing between the printing paper and the tympan, this slight difference may be easily overcome. Several scrapers should be provided of various lengths, so that one of suitable size may be always available to suit the particular work in hand. It should always be slightly longer than the width of the picture, but shorter than the width of the stone or plate. By pressing the edge of the scraper to the surface of the latter and looking towards a window no light should be visible between the two surfaces. If the edges of the scraper are carefully rounded, it may be covered with a strip of wash-leather,[G] smooth side outwards, and secured by means of tacks, by which arrangement the pull will be easier, the impression more even, and the tympan and scraper will last longer. The accompanying sketch represents one of Poirier’s special collotype presses, constructed entirely of iron. The details are so clearly shown in the engraving that after the description already given it will be unnecessary to point out further details.

[G] This is necessary only with metal tympans.

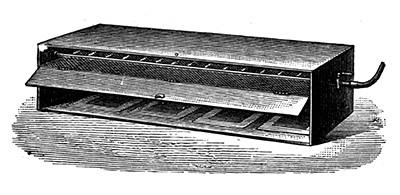

White Margins to Pictures.—To facilitate the production of

pictures with white margins, instead of using a mask of paper either

oiled or treated with a varnish, an arrangement has been introduced,

as represented in fig. 7, the design of which is due to43

44 Mr. Raph.

Schlegel. The drawing is not perspectively correct, but is made to

show as clearly as possible the arrangement and manner of working. The

scraper—not shown in the illustration—works on the tympan .

, carriage or bed of the press, carrying the printing plate.

, a slide of light wood. This prevents the frame and

the printing paper coming in contact with the plate before

the impression is actually being taken by the scraper. The wooden

slide bridges over the plate, and may be 15 to 25 millimetres higher

than the plate itself. When the rolling up or inking of the plate has

taken place the slide is pushed so far forwards as to allow only just

sufficient room for the scraper to rest upon the plate. The action

of the scraper during the taking of the impression causes the slide

to work out, and allows the paper to come in contact with the print

layer. are adjustable buttons to regulate the traverse of

the carriage when printing. is a second frame necessary to

carry the strips of thin zinc, which entirely

protect the edges of the paper to be printed upon, and so produce an

impression with a white margin. These strips may be almost instantly

adjusted to give any required size. The frame must be so

much smaller than the frame as to be easily covered by the

latter, allowing for the projecting screws and nuts of the clamps

. The zinc strips should be reduced to a feather edge on the

sides next the picture, and should have secured to them strips of fine

paper (foreign letter-paper), which45 should extend over the edges

about three millimetres, to prevent damage to the gelatine layer. are clamps for the zinc strips . They are put through

the slots, and the tension adjusted by the nuts. The zinc strips are

perforated by two holes at each end, and secured to the clamps by means

of screws. are also zinc strips; clamps provided

with two holes, in each of which a hook is inserted. Corresponding

with these a second pair of hooks are inserted in holes in the frame

, the hooks being connected together by the strong indiarubber

bands . This gives to the strips a certain amount of

elastic tension. The clamps are also adjustable in slots, and

similar to ; , frame for the reception of the tympan;

, large clamp for stretching the elastic sheet ;

, zinc tympan, greased to facilitate its movement under the

scraper, it also prevents grease penetrating the sheet ;

, a bracket on bed , against which the tympan frame

rests when raised and thrown back. The arrangement is used as follows:

When the plate has been satisfactorily inked or rolled in, the slide or

bridge is adjusted over the plate, leaving a strip of about

three mm. uncovered to allow of adjustment of the scraper. Lower the

frame in which the zinc strips have been adjusted to the size

of picture; the printing paper is placed over this slide, and covered

with a few sheets of paper backing. The tympan frame , together

with the sheeting and greased zinc plate, are lowered upon the work,

the scraper adjusted, and an impression taken.

GELATINE.—The basis of the Collotype process is gelatine—the finest purified animal glue—and the important part it plays in the process demands an acquaintance with its properties, which are found to differ widely, according to its origin and method of preparation. Gelatine suitable for Collotype should be free from all impurities—particularly alum, which is not infrequently added in small quantities during manufacture. Dr. Eder, in particular, has made most minute examinations of various samples, more especially with regard to their suitability for Collotype, Carbon, and the Galvanographic processes, and his opinion, agreeing with that of other experimentalists, is here quoted:—

The two principal modifications of gelatine are those produced from bones, sinews and skins of animals, and from the air bladder of the sturgeon, the latter variety, better known under the name of isinglass, represents, from a chemical point of view, glue in the purest form. On account of its high price and ever-varying quality as found in commerce, it must in practice give place to a glue or size containing chondrin, and prepared from bone and gristle. Another objection47 is, that plates prepared with an admixture of isinglass are less durable than those containing gelatine only. On the other hand, it certainly possesses advantages of its own, which will be more fully considered hereafter. A gelatine suitable for collotype must absorb plenty of water and swell out, but not liquefy after having been soaked in cold water for twenty-four hours. Gelatine or isinglass prepared from the bladder will not stand this test, but, on the contrary, partially disintegrate. The consistency and bearing capacity of a jelly formed by dissolving gelatine in water by means of heat and allowing it to cool, form, in the opinion of Lipowitz, a safe and reliable means of forming a judgment as to its suitability for collotype. Dissolve by first soaking five grammes in 45 cm. of distilled water for several hours, afterwards apply heat, and allow to stand twelve hours to set. For purposes of comparison this should always be done in a glass of the same diameter. A small tin or zinc slip is placed across the top of the glass vessel containing the jelly; through the centre of the tin a hole is pierced, through which a wire moves easily up and down. To its bottom end is soldered a piece of tin, of about 15 cm. diameter, the convex side lying upon the surface of the gelatine. On the other or upper end a small funnel is placed, large enough to contain 1-1/2 kilo. of small shot. The weight of the wire and funnel being ascertained, it will be a simple matter, by also weighing the shot, to calculate the weight required to sink the instrument48 into the jelly, and to ascertain with accuracy its weight-bearing capacity and proof of the relative value of various samples for Collotype printing. If otherwise suitable, the variety capable of supporting the greatest weight before yielding will be the one to select. The power of absorption of different samples varies considerably; for example, the Collotype gelatine of Creutz absorbs in two hours 30 parts of cold water poured over it. Nelson’s patent opaque, in the meantime, only absorbs five parts, but after a further period of 4-1/2 hours the difference is equalised, as it will absorb 25 parts more of water, making altogether exactly 30 parts. This experiment proves the latter to be a harder quality than that of Creutz, and it necessarily requires a somewhat different treatment for the production of the best results.

Isinglass or fish glue, although, as before stated, a finer quality of glutin than the ordinary gelatine of commerce, is, on account of its high price and varying quality, comparatively little used. The addition of this substance also softens the gelatine layer. On the other hand, it possesses certain properties which render its use at times desirable; for instance, it does not dry so completely as gelatine, the layer prepared with it consequently gives cleaner and more even proofs, a point particularly noticeable in the earlier impressions. Such prints will also exhibit greater brilliancy, and this is of especial consequence in work produced from photographs from nature, in which class of work the half-tones are too49 often wanting. Some operators take even equal parts of isinglass and gelatine, but such layers must be very thin, and dried quickly. Thick layers are liable to crack or fly, and in use to refuse to take the ink, which must for such film be used in greater quantity and thinner than when gelatine alone is employed. A solution of isinglass is not so readily prepared as one of gelatine. It is necessary to allow it to soak in cold water for from twelve to twenty hours, and the temperature then gradually raised to nearly boiling point, at which heat it should be maintained for some time longer, and then filtered through flannel into the gelatine solution. In printing from these plates, particularly when the proportion of isinglass exceeds one-third the amount of gelatine, there is a disagreeable tendency of the printing paper to adhere in the high lights—that is, in those parts of the print layer which are represented in the negative by entire opacity—as in the sky of a landscape or a background which has been “stopped out” on the negative. On other portions of the plate where the light has more fully acted—during the printing in the printing frame—this troublesome defect will not be observed. The fault is more noticeable when the dull enamel paper is used, while a hard, well-sized letter paper presents the other extreme. Further details of printing papers will be found in another chapter.

In the introductory chapter of this work the photo-chemical qualifications of the bichromates of50 ammonium and potassium with regard to collotype are considered.

Bichromate of Potassium is found in the well-known rich orange-red crystals. It is readily soluble in cold water (1.10). It may be easily recrystallised and purified readily out of either a hot, warm, or cold solution, and forms in thin layers of fine crystals. Therefore, in using it for collotype, care is needed not to exceed the strictly necessary proportion, as the plate may be hopelessly spoiled by the partial crystallisation of the salt, which will probably show during the process of drying. The maximum addition of bichromate of potassium in proportion to the weight of the gelatine may differ according to the peculiarities of the latter. Dr. Eder considers about 3/10 to 4/10 by weight of this salt in a dry state may be added to a gelatine, which will absorb from six to ten times its weight of water, without fear of crystallisation. There are, however, many gelatines that are incapable of working with more than 2/10. Rapid drying of the plate in a current of air, and at a temperature of 40° C., will, to some extent, obviate this objectionable feature. By reason of its comparative insensitiveness to light and this facility of crystallisation, and notwithstanding its comparative low price, it is now far less used in collotype than

Bichromate of ammonium, the crystals of which somewhat resemble those of the potassium salt. In colour they are of a browner hue, and readily51 distinguishable, since when heated on platinum deflagrates, emitting sparks and leaving a residuum of very finely-divided oxide of chromium. The ammonium salt does not, however, so readily crystallise on account of its considerably greater solubility in water compared with bichromate of potassium. By comparison, 12 parts of the ammonium salt are equal to 15 parts of that of potassium. At least 1/3 to 1/4 more of the former may be used without disadvantage or fear of it crystallising out; it will, on the contrary, improve the quality of the film or layer. The ammonium salt will also be found comparatively more soluble in hot water, but care must be exercised that the solution never reaches the boiling point, neither should the heat of the drying box ever exceed 50° to 60° C., or the films will present a pale brown appearance, and will prove alike insensitive and partially insoluble. The single and tri-salts, offering no advantages over those already described, may be dismissed without further consideration. It may be remarked for non-chemists that the addition of any acid to the chromated gelatine solutions inclines to the formation of trichromates of the alkalis; and, on the contrary, the addition of free ammonia, or any other free alkali, produces simple chromates. The addition of ammonia to the chromated solution has been strongly advocated in many quarters, but as the result of numerous experiments, it may be definitely stated that the supposed advantages are more than counter-balanced52 by the numerous disadvantages arising from such addition. The mixing, in equal or other proportions, of the potassium and ammonium salts has been recommended, but there is no real gain or sufficient reason for preferring any of these combinations to the ammonium salt alone. Besides the chromates of the alkalis, several other salts as well as acids are used in Collotype printing, although seldom, and then only in small quantities and for special purposes, such, for instance, as hardening the print layer, or for the purpose of facilitating the retention of moisture in the film. For the former purpose small quantities of chrome alum are sometimes added; while for the latter chloride of sodium or chloride of calcium are sometimes added to the chromated gelatine solution at the time of coating the plates, or are added as ingredients to the so-called etching or damping solution which is frequently applied to the plates during the printing. Glycerine answers for this purpose, and is to be preferred. It should be borne in mind that all additions to the film to facilitate its retention of moisture lessen its adhesiveness to its support. And with regard to the direct addition of the substances mentioned to the film during the preparation of the plates, it is not very apparent how such readily-soluble matters can remain in the film after the prolonged and careful washing the plates should be subjected to after exposure in the printing frame. On these grounds the addition of such substances53 to the damping solution is more rational and certainly more effective.

Alum and Chrome-Alum causes the gelatine to set sooner without precipitation, and harden the layer considerably after drying, and although gelatine, as well as glue, always contains more or less chondrin, which is precipitated by alum, great care is necessary in the addition of the latter; and it is better that such addition should be made immediately before the hot solution be poured upon the plates, otherwise a precipitation will ensue, which, although very finely divided and at first scarcely visible, will become more apparent during the drying of the plates, and finally show in the picture in innumerable white spots.

Silicate of Soda is almost indispensable as a substratum in the preparation of collotype plates, although many practical workers still adhere to the method originally proposed and practised by J. Albert, of Munich, who used as a substratum a chromated solution of gelatine and albumen, rendered either partially or wholly insoluble by exposure to light. The silicate is here considered as having about the consistency of syrup. If more fluid the adhesive power of the substratum will not realise expectations, and the plates will require very careful handling if even a few hundred impressions are required.

The composition of the film, the exposure of the plate through the back, and the careful treatment54 of the layer in the actual printing operations are all matters which considerably affect the “life” of the plate, and to which we shall again return.

Chloride of Zinc is used for hardening special parts of the collotype plate, and is easily prepared by dissolving—to saturation—sheet zinc in hydrochloric acid, filtering, and reducing as circumstances may demand.

Tannin and Tannic Acid in strong solution harden the film, and may be applied to certain parts to cause it to “take” the ink. For instance, to remove, or rather harden, spots which refuse the ink and consequently show upon a dark ground; and also to write names or titles to the plates. Written additions of this character must, of course, be reversed, as in lithography. The addition of tannin to the chromated gelatine before coating the plate is recommended by Waterhouse, he considering such addition confers greater lasting power to the films so treated.

Cyanide of Potassium and Ammonia.—All alkalis or carbonates of the alkalis have a directly opposite effect upon the printed layer to that last referred to. By the judicious use of one or the other of these agents spots printing light or dark may be either removed or considerably modified.

Glycerine and Sugar and similar easily soluble organic substances, added to the chromated gelatine, would assist the easier and evener damping of the plate, but render it more susceptible to55 damage, and the desired effect is better attained by suitable additions to the damping water.

Organic Acids.—Citric acid and tartaric acid are recommended as additions to the chromated gelatine, partially as influencing the so-called “grain,” and also as additions to the damping solution to facilitate the production of cleaner prints. Experience with these substances shows that the print layer suffers from their use, and for clearing up a plate inclined to yield dirty impressions a weak solution of ammonia is far preferable.

Nitric Acid has even been recommended for occasionally damping the plate in certain cases, after which the most delicate half-tones should be reproducible. An experienced collotypist ought never to be under the necessity of adopting such desperate remedies, which more often than not rapidly and entirely spoil the plate, and it is better to at once prepare a new one.

Ox Gall remains to be mentioned as exercising a beneficial influence upon the print layer under certain circumstances. It considerably hardens the gelatine, and tends to reduce the annoying tendency of the film to adhere to the paper in the high lights. Ox gall was first used at the Royal Printing Works in the “glass” printing process there utilised for the reproduction of line subjects. Some operators of eminence consider that in collotype its use should be strictly confined to lineal representations, as by its continued use the half-tones are partially lost.

Of great importance is the careful selection of the materials for the printing proper—i.e., the printing inks and papers, and the sometimes necessary admixtures of the former.

Printing Ink.—The most simple and suitable of all greasy or oily printing ink is the best chalk ink, as used in lithography. It is composed of finest lamp black thoroughly incorporated with boiled linseed oil (varnish). The collotypist must, in addition to different coloured ink for mixing with the black, be provided with thin boiled oil (middle varnish), and also turpentine and olive oil, the latter being used to thin or reduce the printing inks, which, as usually supplied to the trade, are too stiff for immediate use. When in printing it is necessary or intended to use an admixture of several colours, they must be first well ground in turpentine and the latter allowed to evaporate. A small addition to the chalk ink of indigo or Prussian blue greatly improves its colour and printing power, but may be considered more suitable for the reproduction of line or stipple subjects. A dash of Venetian red or carmine imparts to the chalk ink a warmer tone, resembling the colour of an ordinary silver print. Whoever ventures on colour printing must be able to prepare all the necessary combinations with the greatest exactness, and should use for each a special inking slab and roller. In the chapter dealing with the printing, further particulars will be given as to the mixing and thinning of the colours.

57 The Quality of Paper suitable for collotype may be next considered. Without doubt the best is that known as dull enamel, or chalk paper, which is now supplied of a pink tone as well as of the ordinary white quality. It should not be glossy or adhere too strongly to the printing surface, as the enamel will, under such circumstances, be partially or wholly torn from the paper, a difficulty equally observable whether the paper be used damp or dry. As previously observed, the adhesive power of the printing surface increases with the softness of the same. This may arise from using a small percentage of bichromate or a short exposure to light, in which cases it is always more apparent in such parts, as the densest portion of the negative may have been entirely protected during the copying in the printing frame, or it may arise from the addition of too great a proportion of isinglass. On the other hand, a gelatine film strongly chromated, proportionately longer exposed, and in which there is no isinglass, will be less likely to exhibit this annoying tendency.

Well-sized fine glazed papers generally adhere least, and are usually laid on dry. When the impressions are to be issued without glaze very thin fine-surfaced cardboard—not enamelled—is frequently used, and the margin of the printing plate covered with a suitable mask. Any well-sized paper possessing a fine surface may be used. Impressions58 on such paper may be passed through a weak solution of gelatine, and after drying, rolled, varnished, mounted and again rolled. Any retouching must be done immediately after the sizing, and before the application of the varnish. Enamelled papers require a special glaze, not a lacquer, or are finished without glaze at all.

THE well-polished glass plate must be thoroughly cleaned with alcohol and ammonia, and it should be ascertained that the surface is entirely free from scratches. It is then coated with the substratum, consisting of a dilute solution of silicate of soda and albumen. The following formula is in constant use by many practical workers of experience, and answers every requirement:—

| Distilled water | 8 | parts. |

| White of egg—whisked | 7 | ” |

| Silicate of soda (of the consistency of syrup) | 3 | ” |

This mixture should be well beaten to a froth or put in a bottle with pieces of broken glass, well shaken, and placed aside to settle for half-a-day. Then filter through paper, which should be replaced so soon as the pores become choked. To facilitate the operation the filter paper should before use be moistened with distilled water. The surface of the plate should be flooded with water, and coated as evenly as possible with the above solution, a small glass rod being made use of to assist the flow. Air bubbles must be removed, and by quickly tilting the plate the superfluous solution run off; this should not be used to60 coat other plates without being again carefully filtered. If the substratum be thin, it is not necessary to wash the plate after drying, but after standing aside two days to harden, with dusting and warming, they may be coated with the chromated solution of gelatine. If small crystal formations appear on the surface the plate should be well washed and again dried before proceeding further. The following formula for substratum is due to M. Thiel, senior; it contains less silicate, and the washing before applying the sensitive coating is never necessary:—

| Distilled water | 36 | parts. |

| White of egg | 20 | ” |

| Silicate of soda | 6·2 | ” |

Stale Beer.—Albumen is sometimes replaced by beer, from which by frequent outpourings the carbonic acid has been removed, and to which caustic potash has been added until it fails to show an acid reaction when tested with blue litmus paper (about three to five grammes of caustic potash to the litre of beer will be necessary). To a litre of beer so prepared is added 1/3 kilo. of silicate of soda. The main points in this and also the following operations are careful filtration, even coating and drying in a clean place entirely free from dust. Plates previously used or somewhat scratched must before further use be thoroughly cleaned and the face reground with the finest emery powder.

The Sensitising Solution.—This is manifestly the most important matter in the Collotype process, for on it depends not only the durability of the61 printing plate, but also the method of procedure in the subsequent operations. It may be here intimated that plates prepared by the very best formula cannot be expected to yield good impressions if the whole of the manipulations are not carried out with the greatest care, and it should be noted

1. That neither too much nor too little of the chromated gelatine should be allowed to remain upon the plate. It is impossible to lay down a hard and fast rule, and the exact amount must be determined by the experience of the operator. Of equal importance, and naturally connected with this operation, is

2. The even distribution of the solution, the flow of which may be assisted or directed by the aid of a small glass rod, and by allowing it to run off more or less at each of the four corners of the plate. Considerable experience has demonstrated that the coating is applied most easily and in the evenest manner by resting the plate—previously warmed to about 45° C.—as horizontally as possible on the cork of a heavy bottle, the latter standing in the centre of an earthenware dish. A sufficient quantity of the solution, carefully filtered, and heated to 45° to 50° C., is then poured on to the centre of the plate and rapidly spread over it with a glass rod, previously well warmed. So soon as the surface of the plate has been entirely covered a further supply of the hot gelatine solution is quickly poured on and partially run off at each corner. A scarcely perceptible inclination62 should be given to the plate, otherwise the layer will be too thin; it ought to be about the thickness of four or five sheets of Rive paper of 8 kilo. per ream. It should be borne in mind that the addition of isinglass will necessitate a comparatively thinner layer than when gelatine is used alone.

To obviate the gelatine coating becoming uneven great care must be exercised in removing the plates—when coated—to the drying-box, the levelling screws of which have been adjusted with great accuracy. The box should be heated to a temperature not exceeding 50° C.

To satisfy the adherents of isinglass, two eminently satisfactory formulæ are here given—

| With Gelatine only. | ||

| Collotype gelatine | 6 | grams. |

| Water | 700 | ccm. |

The gelatine is first soaked in the water for one hour, and then complete solution effected at a moderate temperature, and the solution filtered through best filter paper. Boiling heat is never required. Japanese filter paper is the very best. Heat will be necessary during the operation, which may be conducted either in the drying box or a warm oven. When filtered, add, with constant stirring, 8 ccm. of a solution of bichromate of ammonium in water (1 in 8, so that 8 ccm. solution contains 1 gramme of the ammonium salt), which should also be thoroughly filtered before addition to the gelatine.

63 The combined solutions being well incorporated, clear and free from air bubbles, should, as previously described, be heated to 40° or 50° C., poured upon the warmed plate, and at once conveyed to the drying box, the temperature of which has been slightly raised. The box should be closed, and gradually increased to 50° C., at which heat it should be steadily maintained until the drying is complete, which usually occupies one to one and a-half hours, varying somewhat according to the thickness of the coating and the strength of air current, which is necessary to the proper and rapid drying of the films. It may, under some circumstances, be necessary to augment the admission of air; this may be done by slightly raising the lid of the drying box. The current must freely circulate in all parts of the box, and remain as constant as possible. If subjected to sudden fluctuations in the air current or temperature, the plates will dry unevenly, and endless troubles ensue.

The Grain.—The so-called grain which is necessary for the printing first shows itself on the completion of the washing of the plates after printing in the copying frame. It is a peculiar, net-like formation, varying in fineness, and similar in character to the unwelcome appearance known to carbon printers as reticulation. It arises in consequence of the uneven distribution of the soluble layer in comparison to the substratum. In Collotype, its production is promoted by thicker layers and slower drying at a temperature of 45° to 50° C. The64 addition of isinglass also seems to aid the production of grain. Certain varieties of gelatine which possess great power of absorption give a smaller grain. Creutz’s gelatine may be mentioned as an example of this class. An addition in small quantities of dilute acid, particularly those of organic origin, as acetic or tartaric, tend likewise to the production of grain. Insoluble powders, as of glass or flint stone, may be added, but only in the very finest state of division, and in very small quantities.

Formula with Isinglass. Two grammes of the best Russian isinglass are cut up into the smallest possible pieces with a pair of sharp scissors, soaked in 25 cc. of water for 12 hours, heated nearly to boiling point until solution is effected, and then filtered while hot through close flannel. Cover six grammes of good Collotype gelatine with 50 ccm. of water and allow to stand, heat nearly to boiling point and thoroughly incorporate the two solutions, again, while hot, filter through paper or close flannel. To this is added 11 cc. of the filtered solution (1·8) of bichromate of ammonium, as previously referred to. The complete solution is then heated to 50° C., or should it exceed that temperature it is allowed to cool to it, and the plates warmed, coated, and dried in the manner previously described. It is not advisable to overcrowd the drying-box by attempting to dry too many plates at the same time: it necessitates a too frequent examination of the contents and so interferes with the65 evenness of the drying, and as this is a point of even vital importance no risk should be incurred.

The plates being properly dried allow them to remain in the box for some time longer, the source of heat being either removed or extinguished, and the whole allowed to cool gradually. If the plates are removed too quickly in their fully-heated condition—particularly when thickly coated—the too rapid contraction of the glass will crack and destroy the film; by gradual cooling such accidents are avoided. When finished the plates may be kept in a cool, dry place for two or three days. Many operators keep them this length of time purposely, believing they thereby obtain finer results. The plates so kept must, of course, be thoroughly shielded from actinic light.